NIKKISO CULTURE

2023/12/20

Reflections on Nikkiso’s 70th anniversary [#2 Venturing into the medical and aviation fields]

- Medicalbusiness

- Aerospace

- foundingstory

![Reflections on Nikkiso’s 70th anniversary [#2 Venturing into the medical and aviation fields]](/media/grOL3JbxeQ2KWMz1v6Qq5s8pQkF5F2t4YdLbyvaq.jpeg)

Index

Nikkiso traces its beginnings back to December 26, 1953, making this year its 70th anniversary. Nikkiso has grown in step with the Japanese economy ever since the day Keijiro Oto opened the doors of Special Pump Co., Ltd. In this series, “Reflections on Nikkiso’s 70th anniversary,” we trace the path Nikkiso has traveled so far.

This second installment will take you back in time to see how Keijiro ventured into the medical and aviation fields after launching the pump business.

The inception of a medical business dealing in dialysis equipment

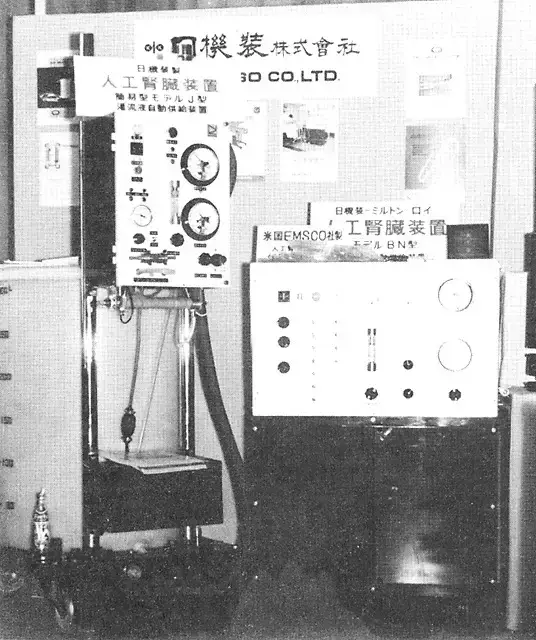

Milton Roy’s Model A—a dialysis machine for a single patient

Nikkiso started out as a distributor of imported specialty pumps before domestically producing its own water-conditioning systems for thermal power plants and leak-free pumps (canned motor pumps) for use in chemical plants in Japan. At the time, Japan was in the midst of an economic boom, and the company achieved significant growth on the back of robust capital investments.

After that, Nikkiso was hit hard by the 1965 recession, which at the time was said to be the largest in the postwar period, and finally fell into the red in 1966.

Behind this fall was a business structure that was susceptible to economic fluctuations. Since Nikkiso operated solely in the electric power and chemical industries, orders would flow in when companies in these industries invested heavily in equipment, but the volume of orders dropped drastically as they cut back on capital expenditures during slumps.

Learning his lesson from the 1965 recession the hard way, Keijiro became keenly aware of the need to navigate rough economic waters. He realized that putting all his eggs in the chemical industry basket would put the company at risk. He knew he had to expand the scope of business operations.

It was then that an artificial kidney machine was successfully developed in the U.S. by Milton Roy, with whom Nikkiso had built a relationship as a distributor of its specialty pumps, as well as through their technological partnership. The American company offered Nikkiso an opportunity to sell its newly developed artificial kidney machine in Japan.

The machine was designed to take blood out of the body, run it through a dialyzer that removed waste from the blood, and return the cleaned blood to the body. Keijiro was impressed with Sheen, Milton Roy’s president, for his visionary application of pump technology in artificial kidney machines designed for dialysis treatment. Coming just as he was thinking about expanding the business, the offer was more than anything Keijiro could have hoped for, and he jumped at the chance to distribute the machine in Japan.

Entering the medical field was a bold move for Nikkiso, which had been operating in the chemical industry, but it wasn’t totally new territory either. About ten years before entering the medical field, Nikkiso succeeded in prototyping the first artificial heart in Japan at the request of a doctor at the University of Tokyo School of Medicine.

It was then that Keijiro realized that the mechanical technology used in the industrial field could also be used for medical applications. This was what sparked his interest in Milton Roy’s artificial kidney machine and why he was ready to plunge headfirst into this line of work.

The first to successfully produce dialysis machines in Japan

The first domestically produced artificial kidney machine (Model BN) developed by Nikkiso

The first domestically produced artificial kidney machine (Model BN) developed by Nikkiso

In 1966, Nikkiso received its very first order for an artificial kidney machine from Hiroshima University School of Medicine.

The following year, Milton Roy’s senior vice president, Dr. Surfas, came to Japan ahead of Nikkiso’s first sale and delivery of medical equipment.. Dr. Surfas,, who was also a talented researcher, worked tirelessly on the test run of the machine, providing technical guidance. He also requested that the pharmacy at the university hospital prepare a dialysis solution based on the dialysis solution he brought from the United States. Thanks to all his support, the equipment was finally delivered.

However, Keijiro felt that relying entirely on imported products would make it difficult to respond quickly to emergencies such as breakdowns during treatment, so he quickly set out to produce the machine in Japan. Shortly after he began distributing Milton Roy products in Japan, he signed a technology partnership with the company and started developing an artificial kidney machine. The following year was 1969, and Keijiro obtained regulatory approval for Japan’s first domestically produced artificial kidney machine.

At that time, dialysis treatment using an artificial kidney machine began to be covered by insurance, and the number of patients receiving this treatment and the number of medical institutions offering the treatment increased, leading to steady growth in Nikkiso's medical business.

Another aspect Keijiro focused on in addition to the domestic production of the machine was the training of healthcare workers.

When Keijiro visited a hospital where patients were being treated, he saw with his own eyes how the fates of people’s lives were literally connected to the machine. He became keenly aware of how precious the artificial kidney machine was to these patients and the grave responsibility now given to those who handled it.

It was a full-scale treatment device upon which a patient's life depended and was being operated by doctors who were medical professionals, but not machinery professionals. Keijiro stressed the need to have on-site technicians who could respond immediately to any malfunction that might arise in an artificial kidney machine.

He soon began training technicians to be machine operation experts who would be able to take urgent action in the event of a mechanical failure.

The first artificial kidney training for customers

The first artificial kidney training for customers

In 1972, Nikkiso started the first medical training program in Japan at its Higashimurayama plant. The one- or two-week course offered at the plant has equipped healthcare workers with the essential knowledge required for dialysis treatment, such as how to operate machines and what to do in the event things go wrong.

So far, over thousands of trained technicians have taken the course, which has attracted people not only from Japan but also from China, Southeast Asia, the Middle East, and other parts of the world. In July 2021, Nikkiso opened a new research and training facility, M.ReT Miyazaki. Today, the company continues to work on enhancing its training programs.

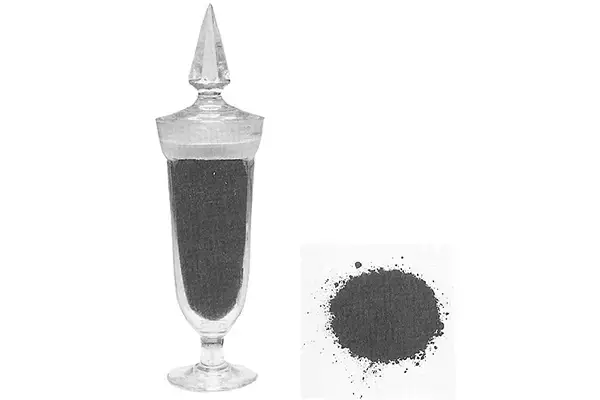

Carbon fiber gives flight to the aerospace business

Fine carbon fiber, graphite whisker

Nikkiso’s medical business grew steadily against the backdrop of an increasing number of dialysis patients. As a number of other companies began entering the market in the late 1970s, Nikkiso started seeking greener fields that could bolster its overall business foundation.

Then, opportunity came knocking once again on Nikkiso’s door. Masahiko Hatano, a former employee of a major textile manufacturer that mainly dealt in synthetic fibers and synthetic resins, had just joined the company. Hatano served as the head of the new materials department and later as president.

Hatano, a friend and colleague of Keijiro during his time at Tokyo Imperial University and in the Navy, had experience in developing and manufacturing carbon fiber. Keijiro suggested that Hatano, who had retired from his previous job, put his experience to work at Nikkiso, where he could really make his mark. This is how Nikkiso came to deal in carbon fibers with Hatano at the helm. Nikkiso began using a part of its Shizuoka plant, where the Medical Business was based, as the launch pad for a brand-new business that would later become the Aerospace Business.

Keijiro and Hatano began brainstorming on what direction to take the new business in. Keijiro noted, “Nikkiso is dedicated to doing high-quality, high-value-added work, so inevitably, prices end up high.” In response, Hatano proposed creating a carbon fiber composite material by combining carbon fiber and resin.

Having experienced bitter competition in the materials industry, Hatano knew that focusing on carbon fiber alone as a material would eventually lead them into a price war. So, the two decided to develop strong but lightweight carbon fiber composites.

They agreed on avoiding the leisure industry, where carbon fiber composites were already widely used. Instead, they would venture into the aerospace industry, which was expected to take off in a big way. They also decided to operate the business with a focus on the United States, where the market was huge, and kicked off research and development with an in-depth look at local needs.

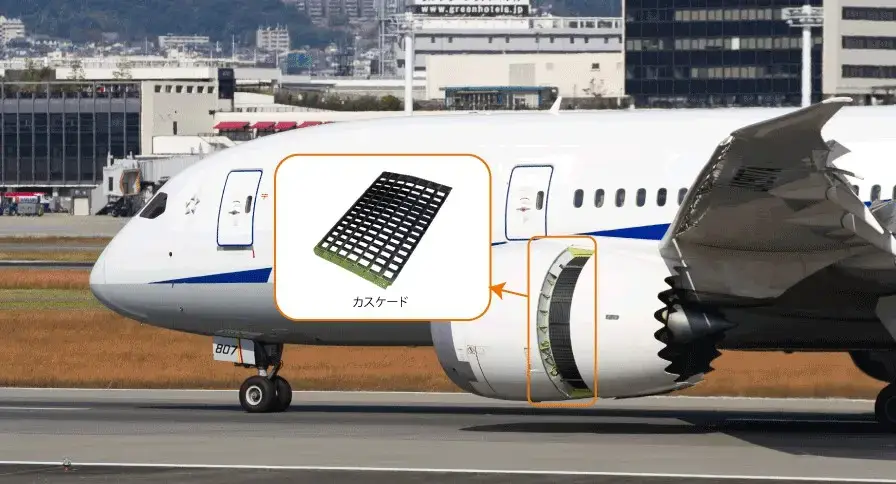

The aerospace business they started from scratch initially failed to turn a profit, but Keijiro saw it as a "healthy deficit" for future growth and continued to work toward achieving results as quickly as possible. The first carbon fiber composite product they received an order for in this new business was the cascade, an aircraft component.

Rohr, Inc., an American aircraft engine nacelle manufacturer, was looking to change the material for their cascades from aluminum alloy to carbon fiber composite. Nikkiso got to work right away on product development to fulfill Rohr’s request. After completing the product design, building the manufacturing process, and undergoing various tests at Rohr, Nikkiso successfully developed the world's first carbon fiber composite cascade in 1983, establishing a firm foothold in the aircraft industry.

Nikkiso’s market share began to soar as the use of carbon fiber composite materials in aircraft gradually increased.

Nikkiso’s vision was not only to develop and manufacture carbon fiber composite components for the aerospace market, but also to focus on technology licensing. The company believed that it should be able to establish a business that sold manufacturing technology and know-how if further research and development could yield something that surpassed existing materials in the market.

Nikkiso continued its efforts to develop technologies in parallel with product development and in 1986, succeeded in licensing its carbon fiber technology to US-based Boeing.

Looking back on the history of Nikkiso

Nikkiso started out manufacturing and selling water treatment systems while dealing in specialty pumps made overseas before expanding its operations that now include:

- the Industrial Business for specialty pumps and systems,

- the Aerospace Business for carbon fiber composite aircraft components, and

- the Medical Business for hemodialysis products.

The company has established a track record of providing original technologies and high-quality products in each sector.

Throughout its history, Nikkiso has always been willing to venture into areas where no one has gone before when necessary, as well as go the extra mile to meet the needs of its customers.

In order to continue to meet the expectations of customers and the demands of society, Nikkiso will continue to diligently refine its technology and service capabilities while enhancing its manufacturing capabilities in ways that only Nikkiso can achieve.

Pickup

-

MEDICAL FIELD

MEDICAL FIELD

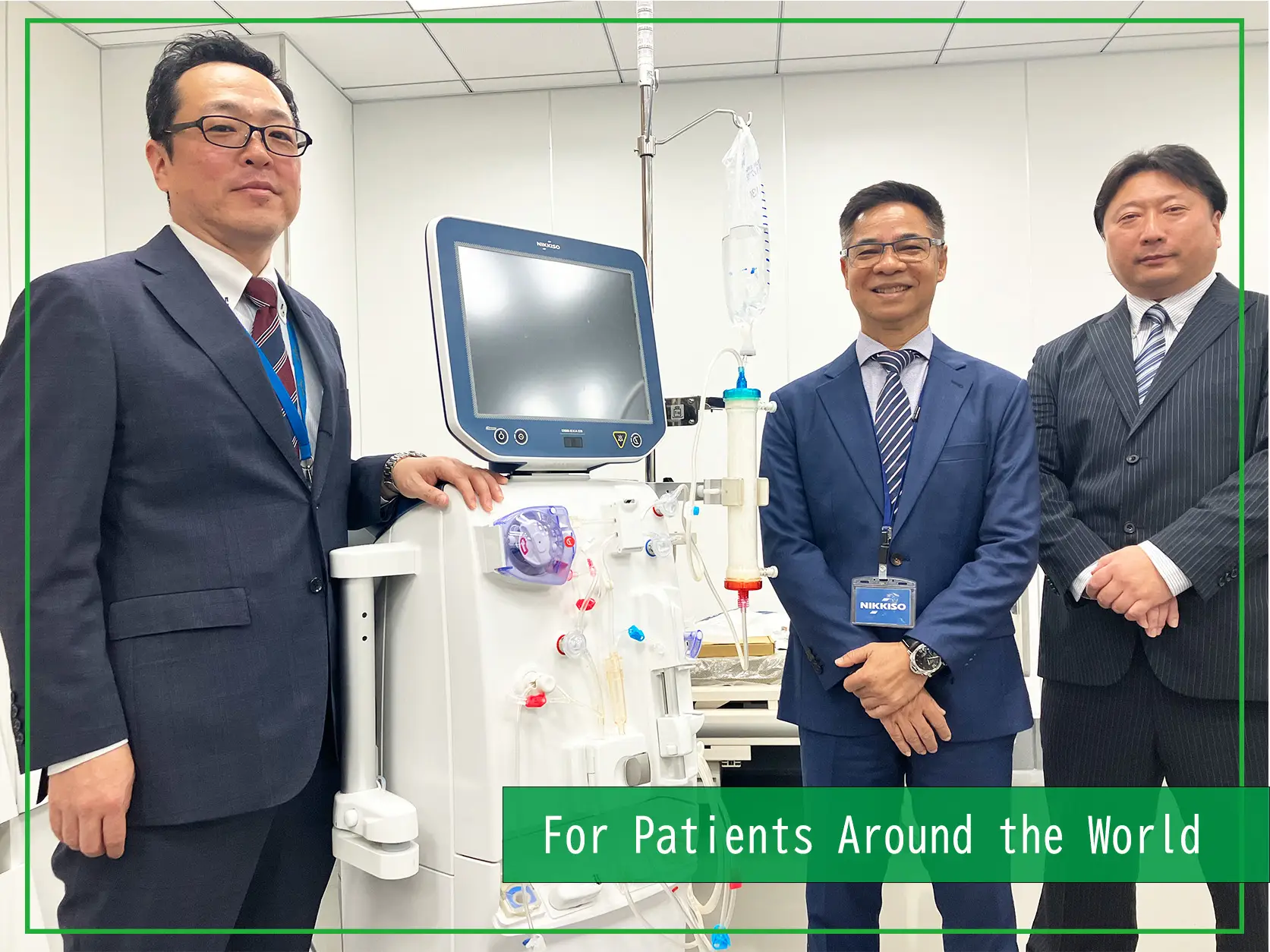

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

MANUFACTURING

MANUFACTURING

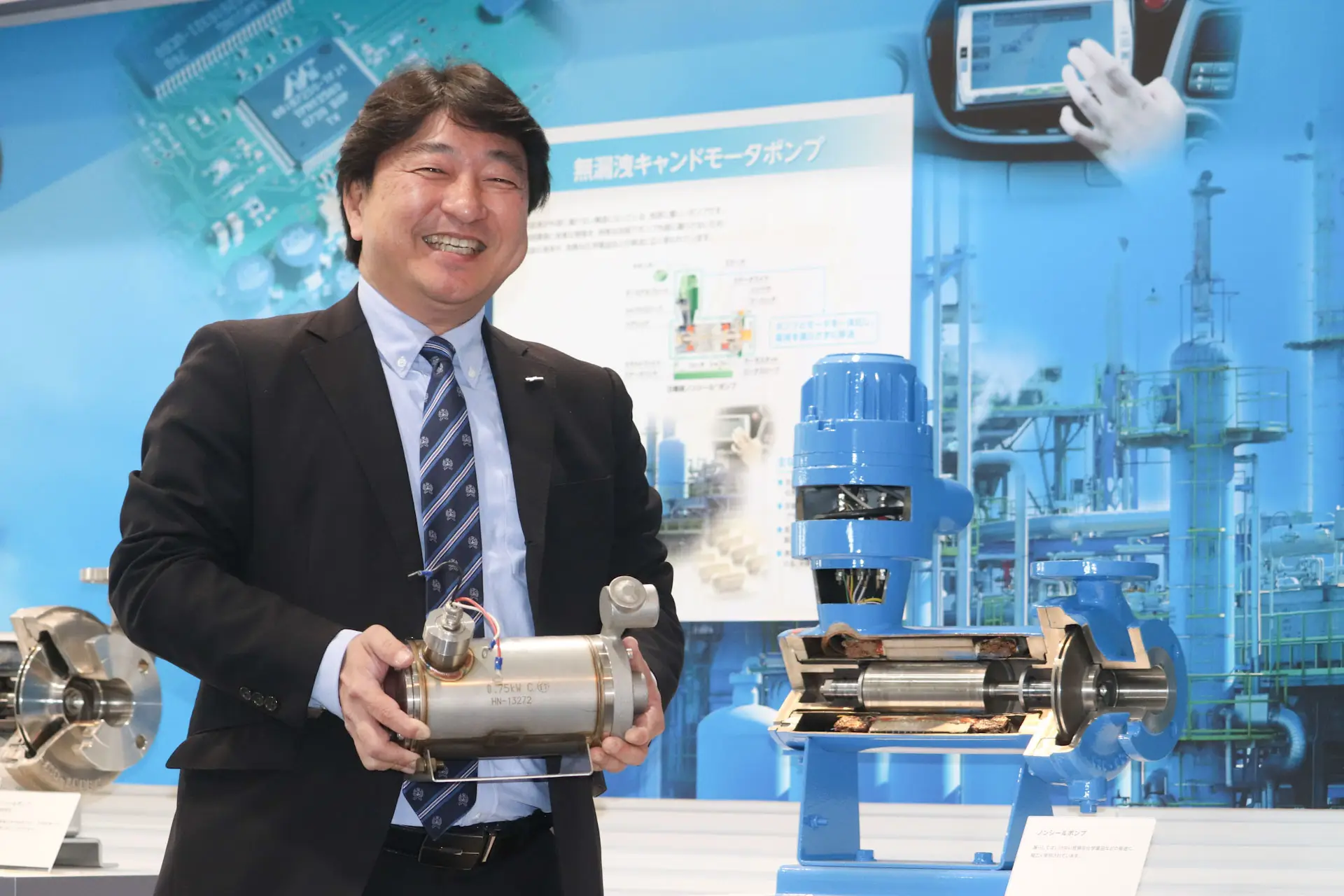

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

MANUFACTURING

MANUFACTURING

Nikkiso's DX initiatives: CAE Support Department continues to evolve, aiming to eliminate dependence on the skills and expertise of specific people

- Technology

- Interview

2025/04/09

関連記事

-

NIKKISO CULTURE

NIKKISO CULTURE

The Nikkiso Institute of Research and Technology tackles research and technological development which transcends business boundaries and takes on the challenge of creating innovation

- Interview

- Technology

2024/12/27

-

![Reflections on Nikkiso’s 70th anniversary [# 1 How it all started]](/media/nx5fObpsRg3bMeP9mciCBF6GSehox5TwxvBGaHrW.jpeg) NIKKISO CULTURE

NIKKISO CULTURE

Reflections on Nikkiso’s 70th anniversary [# 1 How it all started]

- Industrial

- foundingstory

- Pump

2023/12/14

-

NIKKISO CULTURE

NIKKISO CULTURE

Creating even more Nikkiso innovations with the establishment of the Medical Technology Center

- Interview

- Technology

- Hemodialysis

- Medicalbusiness

2023/11/07

-

NIKKISO CULTURE

NIKKISO CULTURE

Nikkiso Arts and Culture Sponsorship Activities: For the Preservation and Promotion of Kaga Inlay

- Kaga-inlay

- Interview

2023/02/28