MANUFACTURING

2025/04/09

Nikkiso's DX initiatives: CAE Support Department continues to evolve, aiming to eliminate dependence on the skills and expertise of specific people

- Technology

- Interview

Index

Today, manufacturing sites must adapt to an ever-changing market and respond quickly to the diversifying needs of society and customers. To survive in this rapidly changing environment, it is essential to build a flexible and efficient manufacturing system through DX, or Digital Transformation.

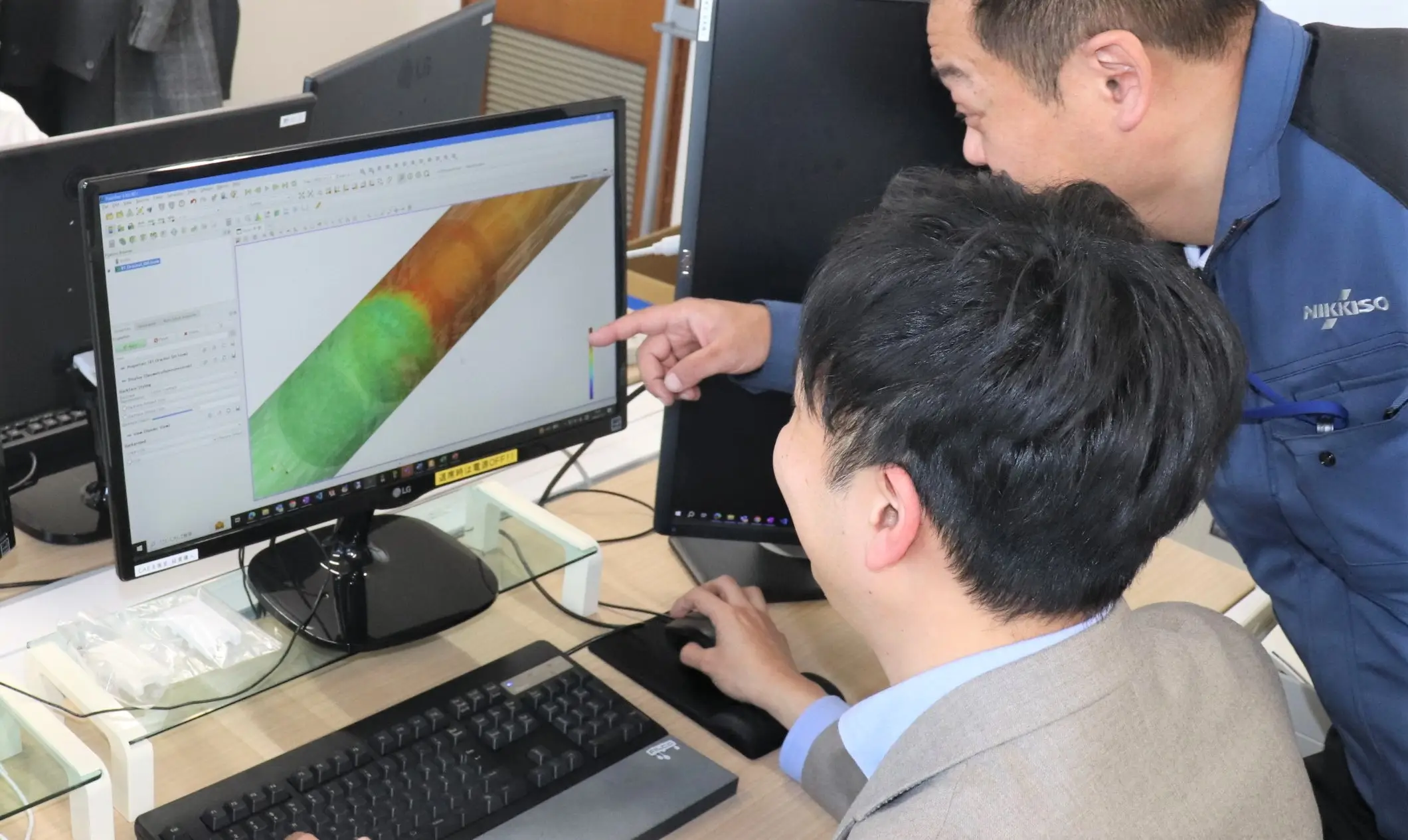

Therefore, Nikkiso has focused on CAE analysis, which is the key to DX, and established the CAE Support Department in 2020. It has been working to improve the efficiency of analysis and development processes.

This time around, we interviewed members of the CAE Support Department. Upon hearing from four members (General Manager Fujishima, Mr. Hiraishi, Mr. Nakata, and Ms. Tajima), the significance of the CAE Support Department and the satisfaction derived from working there became clear.

From left to right: Fujishima, Hiraishi, Nakata

From left to right: Fujishima, Hiraishi, Nakata

Yasushi Fujishima is General Manager of the CAE Support Department at the Nikkiso Technical Research Institute. He is in charge of management and CAE analysis in general. He handles a wide range of areas, including in-house code development and CAE analysis in multiple fields within the company, infrastructure environment development, and so on. Takayuki Hiraishi joined the company as a mid-career hire in 2020. As an expert in plastic injection molding analysis, he is mainly responsible for molding flow, fluid, and structural analyses for medical and industrial applications. As for injection molding, he takes a holistic approach to problem solving while taking mold feasibility into consideration. Takuhiro Nakata joined the company as a mid-career hire in 2022. He is responsible for fluid analysis for medical and industrial applications. He is engaged in both analytical and experimental development with the aim of realizing mass cultures of cells for kidney therapy and the scaling-up of agitators used for that process. Yuko Tajima joined the company in 1995. She is in charge of prototyping and fixture modeling using 3D printers, as well as CAE analysis and testing assistance. She handles 3D printer modeling requests from throughout the company while concurrently performing general administrative duties. *Affiliations and titles are current as of the time of the interview. |

Aiming to be independent on individual skills and expertise. Why Nikkiso is working on DX

—— Thank you very much for your time today. I understand that Nikkiso is now actively incorporating DX. What are the reasons for this and what do you hope to achieve?

| DX = Digital Transformation DX is an initiative involving fundamentally transforming a company's business models, services, technological development, and so on, through the use of digital technology to enhance competitiveness. |

Fujishima: One of the challenges we faced was that there had been no documentation taking place with respect to the knowledge and skills involved in the important tasks which skilled workers were responsible for at our company. With the aim of solving this issue, we are now promoting DX to provide visualizations pertaining to know-how relating to design and manufacturing.

By doing this, we aim to share the knowledge and skills with our younger engineers and to enhance their knowledge and skills. We also believe that it will be useful for developing new products and improving existing products. Through DX, we hope to ultimately create a process that will generate greater profits.

Nikkiso's CAE Support Department: Responsible for company-wide analysis

——As part of DX initiatives the CAE Support Department was established in 2020. What kind of technology is CAE to begin with?

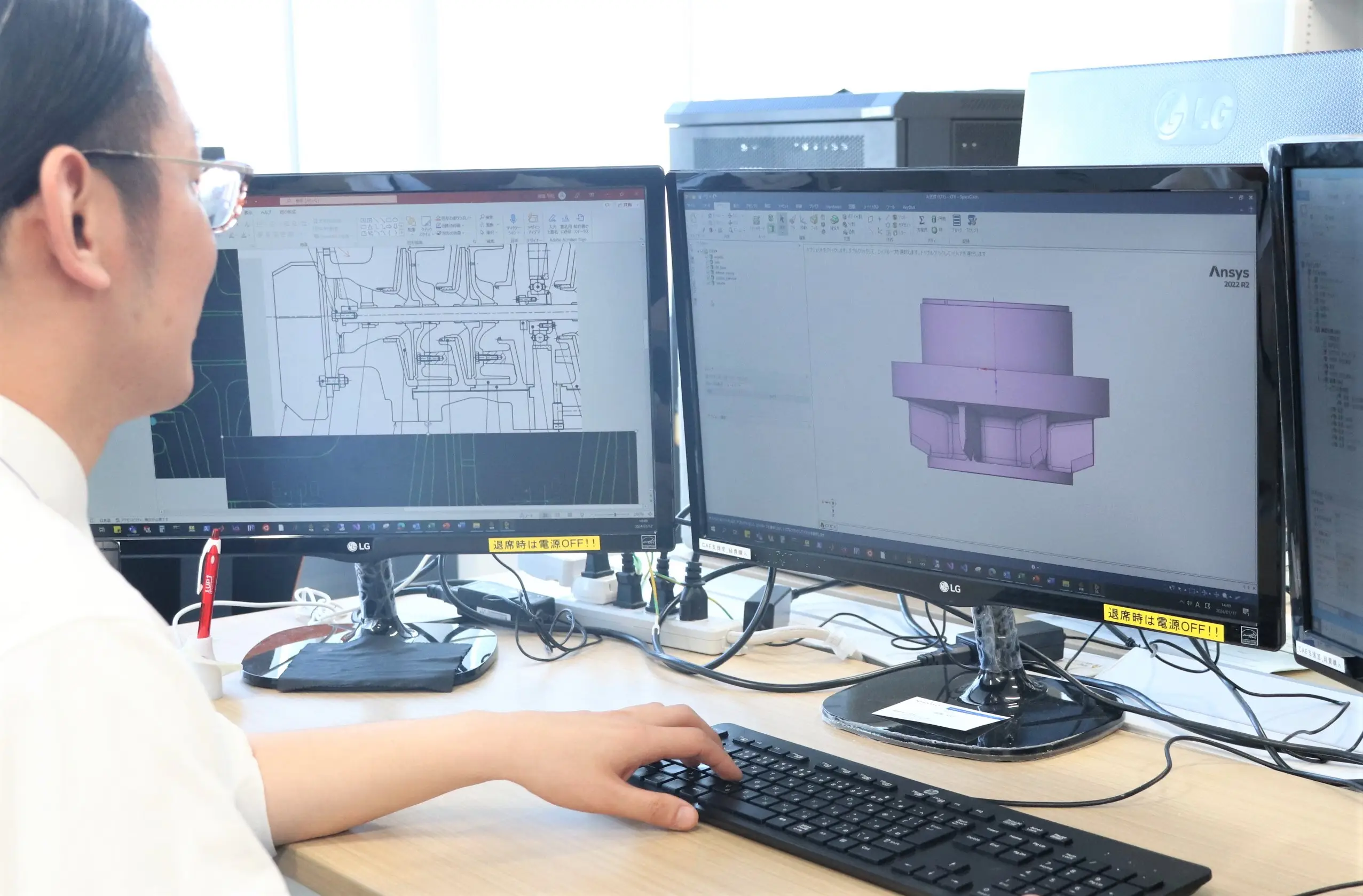

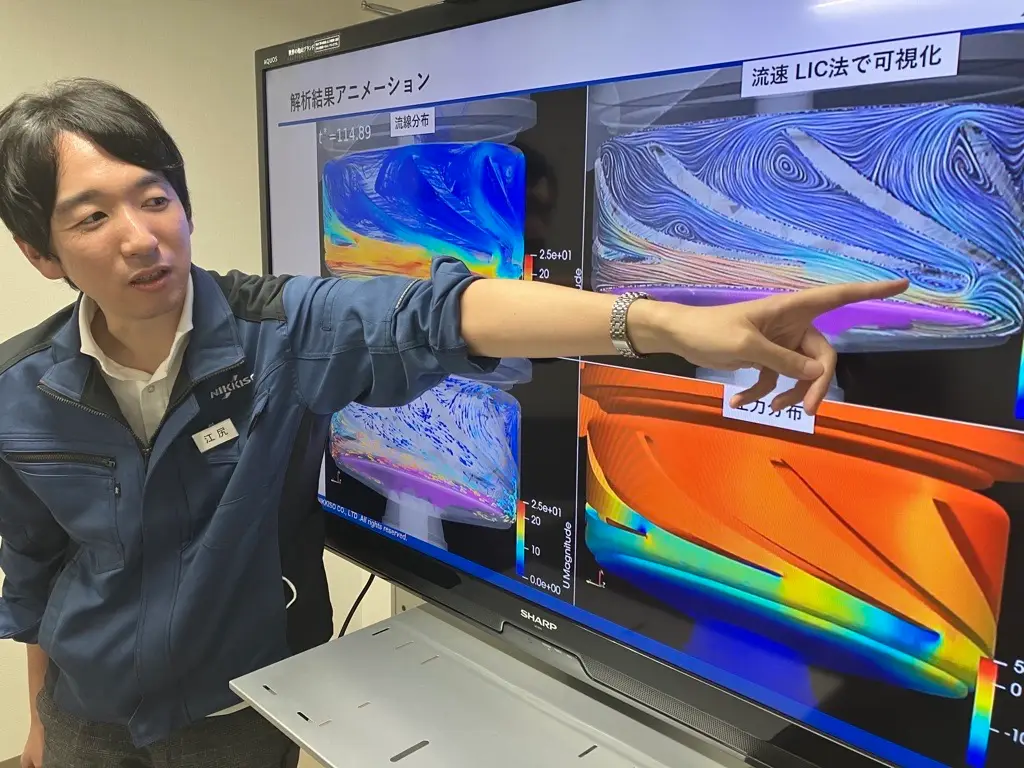

Fujishima: CAE is an acronym for "Computer Aided Engineering," a technology that replaces the traditional experimental process of repeated trial and error with computer simulations. Development time and the costs involved become reduced since all experiments are performed in a virtual environment.

CAE is also effective in identifying the causes of defects and taking countermeasures.

For example, if a defect is found that cannot be anticipated in the design, improvement measures were considered based on rules of thumb in the past. By utilizing CAE, however, the cause of the defect can be efficiently discovered and visualized, meaning that later improvement plans can be formulated smoothly.

There are cases where we cannot determine the cause of the problem without using CAE, as well as cases where we cannot determine the necessary conditions for the product to be viable.

—— What is the main role and mission of the CAE Support Department at Nikkiso?

Fujishima: The CAE Support Department has three roles. The first role is to facilitate the permeatseion of CAE within the company. We started the full-fledged utilization of CAE rather late in the game. The reality is that it has not yet been sufficiently spread throughout the company.

While we do provide in-house training and technical support whenever the need arises, we would first like to communicate the benefits of CAE to the engineers who design and develop each product by actively using CAE and demonstrating its effectiveness in concrete ways.

The second role is to undertake CAE analyses. By undertaking CAE analyses from throughout the company, we aim to establish an in-house foundation for analysis technologies and go about creating new value.

The third role is the construction of infrastructure environments. CAE analysis requires dedicated hardware and software. What's more, building such an infrastructure environment also requires expertise and costs money. We intend to put in place infrastructure for the entire research institute in the future while at the same time supporting the construction of infrastructure that meets the requirements of each Business Division.

—— I understand that Nikkiso's CAE Support Department handles everything related to CAE. Does the section have any unique characteristics not found elsewhere?

Fujishima: Nikkiso's CAE Support Department is characterized by its broad involvement in all of Nikkiso's business divisions. It does not specialize in any one particular field. CAE itself is a highly specialized technology, but each of our CAE support members possesses the flexibility to develop original tools, customize them as needed, and even perform prototyping and experiments.

—— What are the reasons for and advantages of being involved across different fields of business, such as the Industrial Division, Aerospace Business and Medical Business?

Fujishima: Although the contents of these businesses differ, the three businesses all share a commonality in that they all utilize fluid mechanics.

Therefore, if the CAE Support Department can establish a base for fluid analysis technology, it can be used for other businesses with only minor changes to the technology being necessary. While time and effort are required in the initial stages, the advantage of a cross-sectional response is that we can then develop new technologies more efficiently thereafter.

There are other advantages to having a department that is dedicated to analysis. If analyses are conducted separately within a Business Division, issues remain regarding the accumulation of know-how as well as the nurturing of talent. At Business Divisions, once a project that you are in charge of is completed, you are usually transferred to another project immediately. This means that there may be cases in which one's knowledge pertaining to the analysis technology involved becomes lost.

To remedy the problem of analysis technologies not taking root within each Business Division, the CAE Support Department is working on analyses as a specialized department.

—— How many analysis requests are you currently handling?

Fujishima: In the last fiscal year, we received 80 to 90 requests in total. Three years ago, the number was around 20, so the number of projects has been steadily increasing.

In addition, the content of each individual project has recently become more sophisticated. We thus feel the need to have a broader range of knowledge and skills.

Diversified knowledge which transcends fields of specialization serves to create new value

——Next, I would like to ask you about the people who work at the CAE Support Department. What skills or backgrounds does everyone there have in common?

Fujishima: People with a wide range of backgrounds are assigned to the office so that as many of the various needs within the company can be met.

We want all members of the office to be able to see multiple fields, so there is no uniformity in what individuals had majored in during university or in terms of their fields of specialization. Members of the team come from a diverse array of backgrounds. Some are extremely knowledgeable about fluid mechanics, some are extremely capable of structures, some are specialized in thermodynamics, and so on.

—— You have assembled specialists in various fields to respond to requests provided from people and organizations found throughout the entire company. Please tell us about the unique work of the CAE Support Department that isn't found elsewhere and about some of your most memorable experiences there.

Left: Hiraishi / Right: Nakata

Left: Hiraishi / Right: Nakata

Hiraishi: I think it is very interesting to be able to do research and development that focuses on CAE. I am currently involved in research to achieve the practical application of product analyses by utilizing open-source software instead of expensive commercial analysis software. I am also engaged in feasibility studies, such as those involved in drastically increasing the scale of analysis using external supercomputers and computational resources.

Nakata: Work which is unique to our CAE Support Department, is characterized by being able to solve issues for products company wide. I feel that being able to analize various products handled by Nikkiso, such as pumps, precision equipment, medical devices, and aircraft parts, is an experience that one can only have in our CAE Support Department, which handles projects across the company.

Tajima: My main duties are to create CAD data and make models using 3D printers, and then conduct simple experiments using the models I have made and perform the initial analyses. I feel that I am acquiring a wide range of knowledge through the handling of the entire process spanning from analysis to experimentation within the department I work in.

—— I understand that you joined the CAE Support Department as mid-career hires. What are some of the differences between your current jobs and your previous jobs and what has surprised you?

Hiraishi: Every day was full of surprises for me. Originally, I was doing plastic injection molding analyses, but when I joined Nikkiso's CAE Support Department, the number of fields I was involved with analyses had increased. While there are aspects which make me think about how difficult things are and how much I have to learn since I need to obtain a thorough knowledge of fluid mechanics, structures, and heat transfer, I also feel the joy of being able to deepen my learning even as I get older.

Nakata: Before joining Nikkiso, I worked for a CAE vendor. There, I mainly specialized in structural analysis using composite materials for automobiles. Since joining Nikkiso, however, I have also been involved in other fields of analysis, such as fluid dynamics and heat transfer. I think it is a valuable environment that enables people to handle a wide range of analytical fields, as was the case with me.

—— What is the most rewarding aspect of working at the CAE Support Department?

Fujishima: I find it most rewarding when I receive the recognition of the engineers of each respective business. Although there were some harsh opinions given when the CAE Support Department was established, more and more people came to understand the importance of the section as CAE gradually became more widespread. When analysis and technological development projects that take between a year to a year and a half to finish, lead to results, I once again feel that it was a good decision to introduce CAE.

Hiraishi: I find it rewarding when the results of analyses match up with the results of experiments. Even if an analysis is theoretically feasible, modeling studies involve various challenges, such as budget and time constraints, as well as limitations of computing power. After overcoming such difficulties, the moment when the results of an experiment agree with the results of the analysis is a very happy moment.

It is also rewarding when we have been able to eliminate product defects using CAE. To give a specific example, a product that was not compatible with alcohol had to be modified to specifications which would allow it to be compatible with disinfection using alcohol as a consequence of the COVID-19 pandemic.

When we changed the relevant material to a resin material that would not crack even in the presence of alcohol, a problem called "short shot" occurred, in which the resin did not fill the required space partially during the molding process, resulting in defects. Then, after conducting a plastic injection molding flow analysis using CAE, it was found that the balance of the resin injection position was not optimal. We then suggested a change in the injection position and successfully made a good product. That was one of my successful experiences.

The elimination of the defect, I think, allowed us to win the gratitude of the employees responsible for the design of the dialysis machine and their appreciation of CAE.

Nakata: I am currently involved in the development of cell culture agitation devices, which is being worked on in the Industrial Division. I never thought that I would become involved in the regenerative medicine field in my life since I did not study at the department of medicine or the department of pharmaceutical sciences at university.

However, now that I am a member of the CAE Support Department, I am able to contribute to the field of regenerative medicine, a field which supports life from an engineering approach. I feel both joyful and rewarding.

Tajima: I find it rewarding to hear comments from people at other departments with respect to 3D printer modeling, with some of those comments being to the effect that they were able to conduct their experiment as expected or to the effect that they were able to reduce the cost of their molds.

Nikkiso's new challenge toward DX in manufacturing

—— Lastly, please tell us about the new initiatives being undertaken by and the future prospects of the Nikkiso's CAE Support Department.

Fujishima: I would like to contribute through CAE to projects related to decarbonization, an area that the company is actively working on, with involvement in projects such as the development of hydrogen pumps and the design of aircraft using composite materials. I hope that eventually, with the power of CAE, we can serve as leaders of sorts and provide guidance to those working in the field of product development and design.

We also plan to accelerate collaborations with universities. We hope to build win-win relationships for both universities and our company through systems which allow us to receive guidance from university professors and through opportunities for joint research.

In addition to CAE, we will actively incorporate machine learning and mathematical models at manufacturing sites with the aim of further streamlining and optimizing the manufacturing process.

Pickup

-

MEDICAL FIELD

MEDICAL FIELD

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

MANUFACTURING

MANUFACTURING

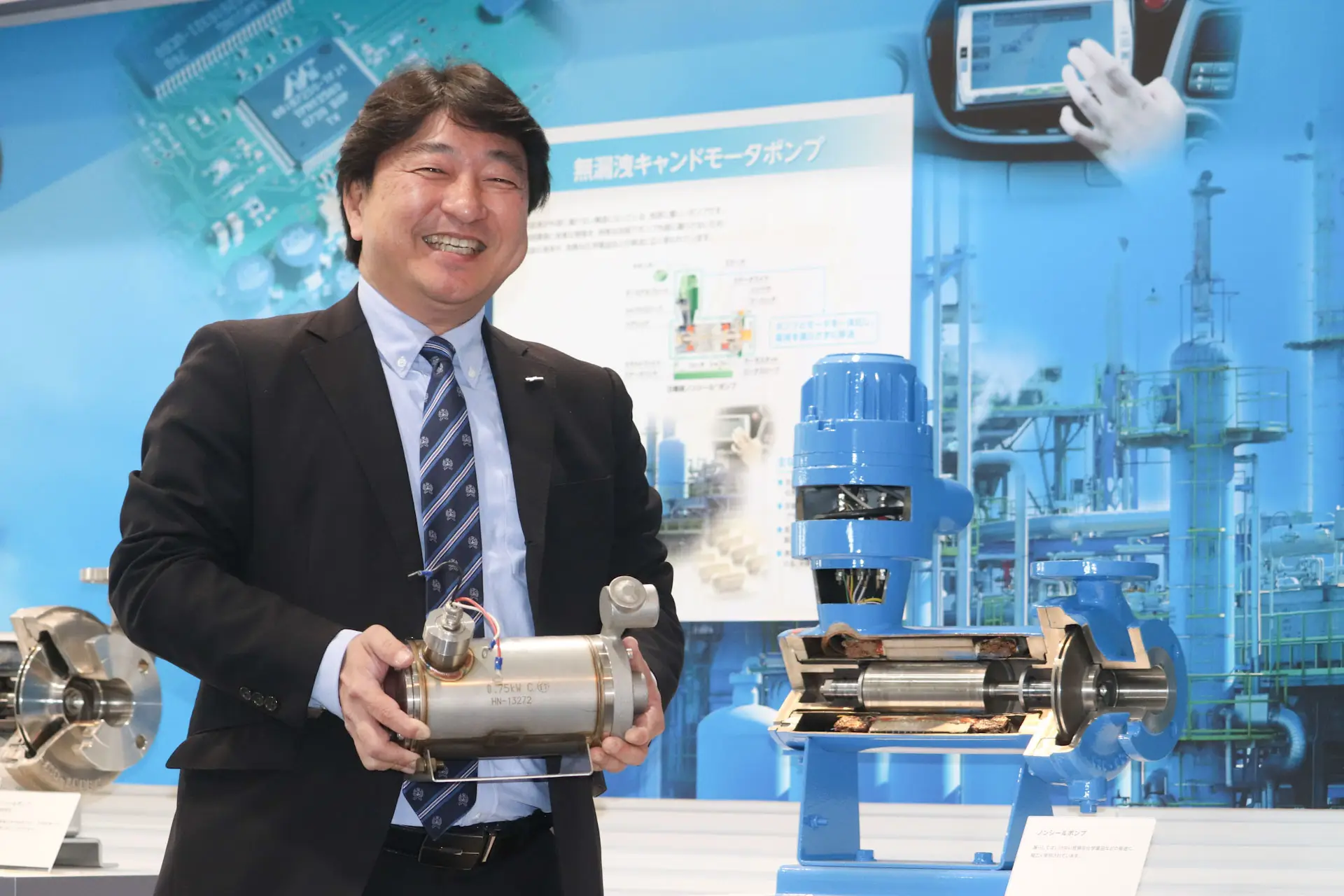

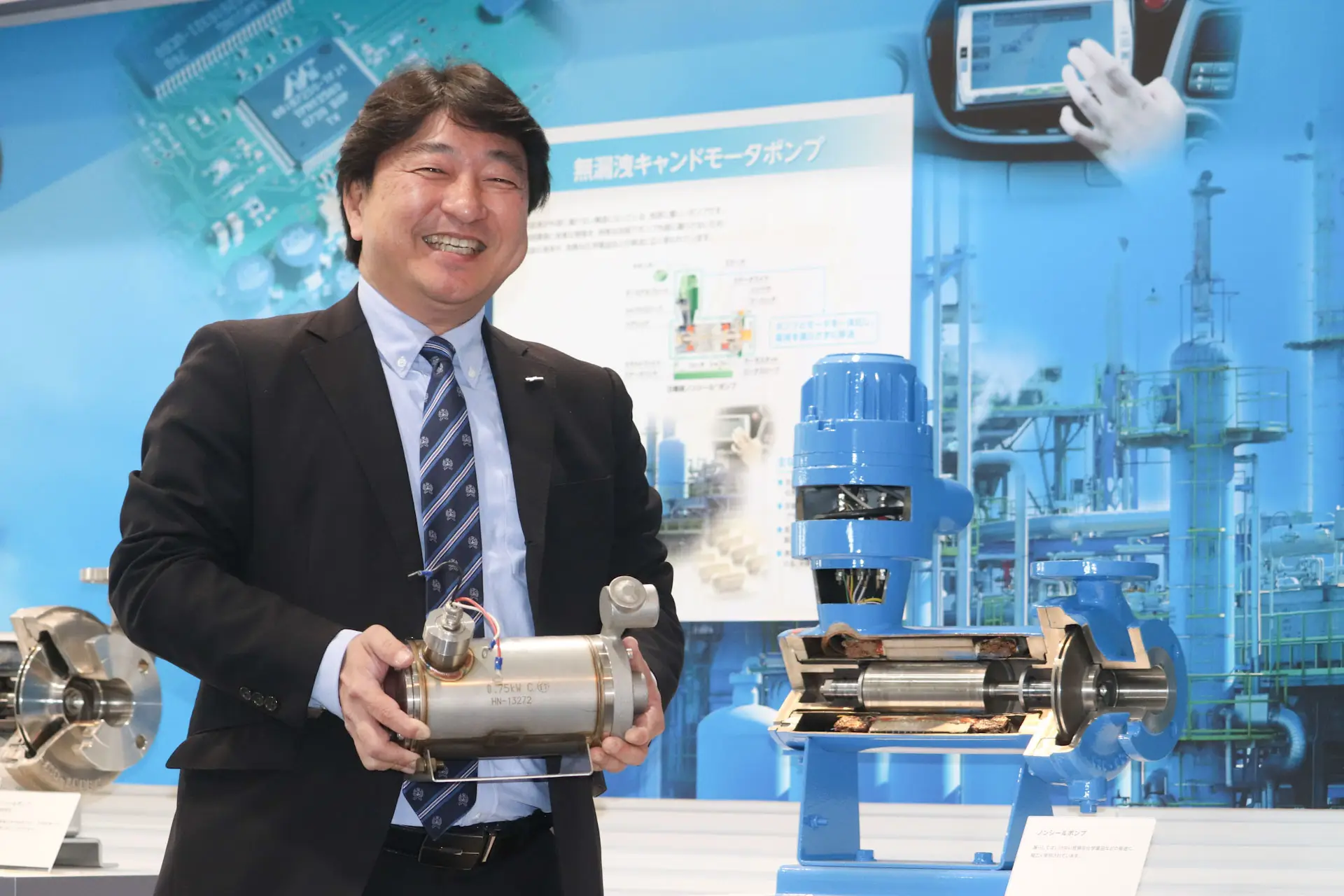

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

MEDICAL FIELD

MEDICAL FIELD

A region on the forefront of dialysis treatment: Nikkiso automation gathering attention in Europe

- Medicalbusiness

- Hemodialysis

- Interview

2025/03/13

関連記事

-

MANUFACTURING

MANUFACTURING

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

MANUFACTURING

MANUFACTURING

Behind the development of the 3D Sinter, a new technology which serves to improve both the quality of SiC power semiconductors and productivity in the manufacturing process

- Semiconductor

- Interview

- Technology

- Industrial

2025/02/19

-

MANUFACTURING

MANUFACTURING

What are the characteristics of technical jobs at companies? What are Nikkiso’s strengths in particular? | Answers to questions from students

- Industrial

- Pump

- Interview

- Technology

2024/09/19

-

MANUFACTURING

MANUFACTURING

Efficiently Manufacturing Eco-Friendly Aircraft Components with CFRTPs | Initiatives for Decarbonization in the Aviation Field

- Interview

- Aircraft

- Aerospace

- Technology

2024/05/16