MEDICAL FIELD

2025/02/13

Faster and more assured treatment: Nikkiso's efforts to develop technologies to improve work efficiency and safety of medical devices

- Medicalbusiness

- Hemodialysis

- Technology

Index

As we see greater shortages of medical personnel occur due to the declining birthrate and aging population, there is a need to develop medical devices that can achieve high performance even where human resources are limited. To respond to this situation, Nikkiso is working on various technological innovations based on efficiency and labor saving.

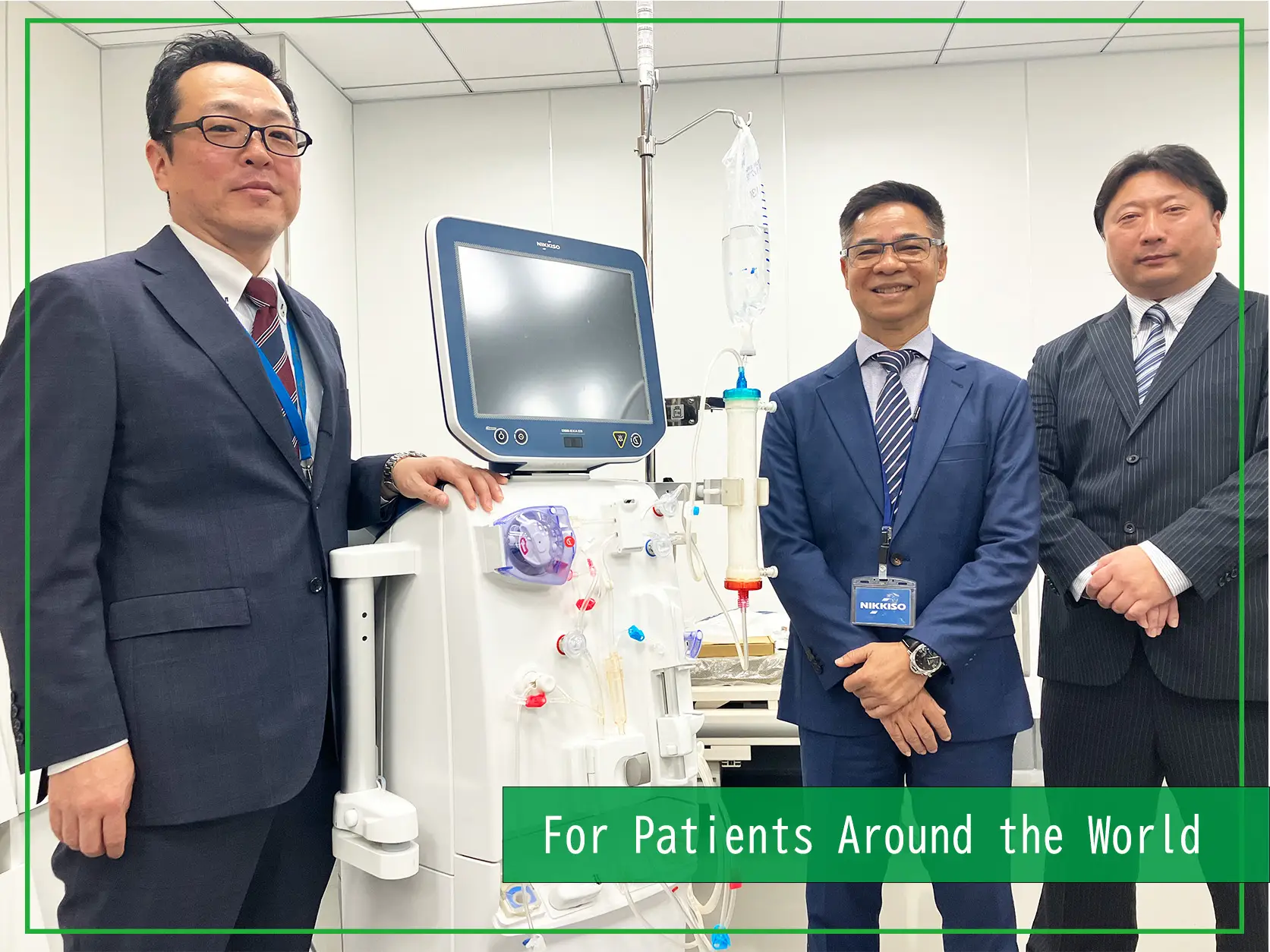

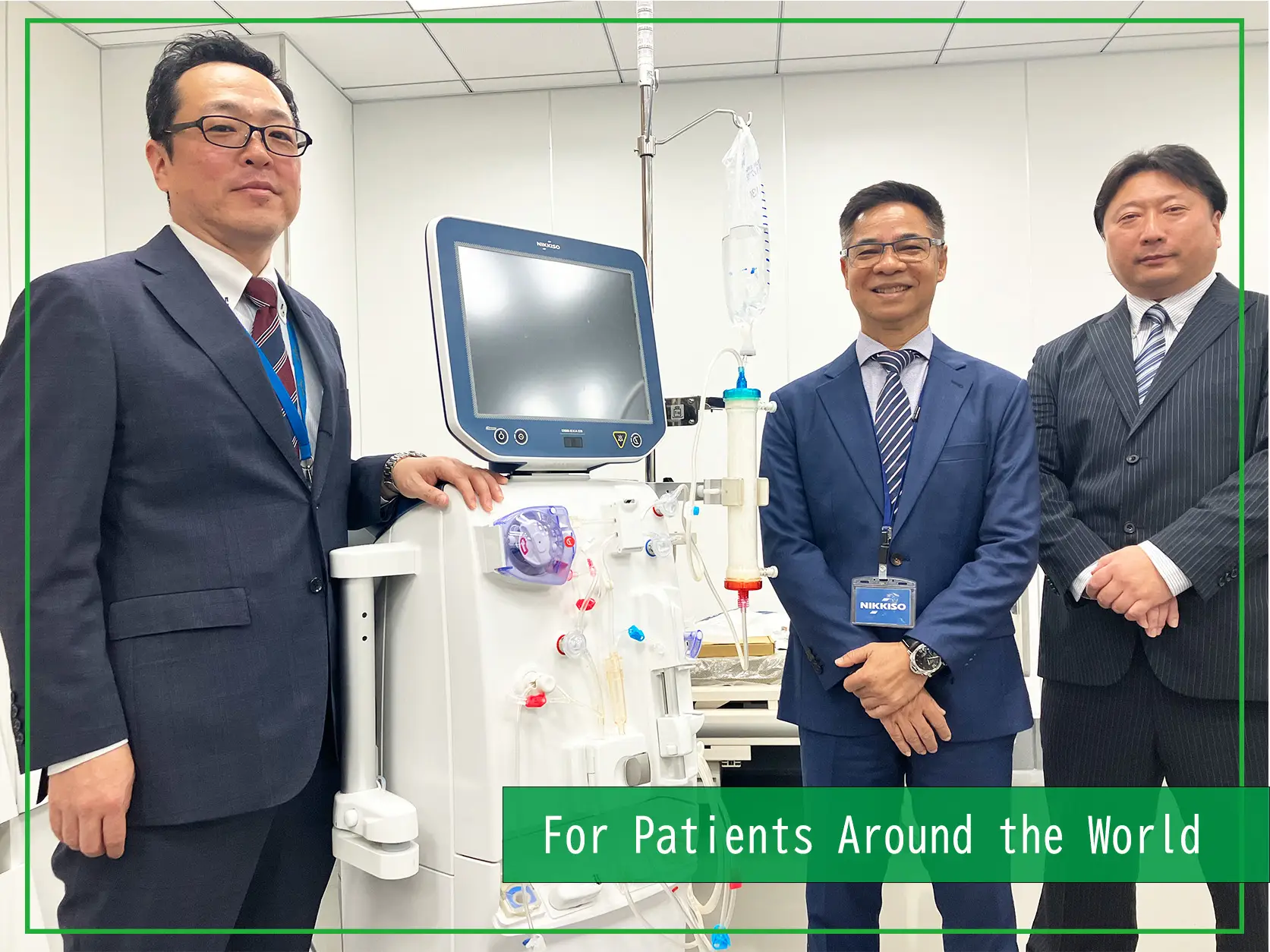

This time around, we interview Mr. Inoue about the challenges Nikkiso faces when it comes to the medical community. Mr. Morita and Mr. Ota, who received the Kyushu Region Commendation for Invention and the Chubu Region Commendation for Invention, respectively, for their solutions to these challenges in the field of blood purification equipment, were also interviewed in detail about the advanced technologies they invented and the effectiveness of those technologies.

Today, we're going to think about what Nikkiso can contribute to the medical community of the future.

Naoki Inoue is General Manager of the Business Promotion Department at the Medical Division. Masaaki Ota belongs to the Engineering Department of the Medical Research & Technology Center at the Medical Division. As group leader, he is in charge of mechanical design, focusing on dialysis machines. Masayuki Morita belongs to the Manufacturing Engineering Department of Kanazawa Plant Medical Products Factory. He is responsible for design and fabrication of manufacturing equipment and molds, and design transfer. *Affiliations and titles are current as of the time of the interview. |

A desire to reduce the burden shouldered by medical professionals: Nikkiso's efforts to improve work efficiency

—— Thank you very much for your time today.First, please tell us about Nikkiso's efforts to improve the efficiency of treatment preparations and cleanups for dialysis machines and blood purification devices.

Inoue: Nikkiso has been on a journey involving the development of dialysis medical care and has responded to a variety of needs for medical care. In the field of dialysis machines in particular, Nikkiso can be considered a pioneer as it was the first company to achieve the domestic production of dialysis machines in Japan.

Hemodialysis is an important treatment that serves to support both life and health. Many patients require treatment every two days for four hours at a time, and thirty to forty patients may be treated simultaneously at a single facility. Some medical institutions employ specialized preparation staff, and the time and effort required for preparation has constituted a challenge in the past.

Nikkiso provides solutions to these issues that are faced by medical institutions to ensure stable and continuous medical care for patients.

—— How difficult is it to prepare for treatment?

Inoue: There are various preparatory processes involved in hemodialysis. There are also many complex processes involved, which means it takes time to get used to everything. Those processes include filling extracorporeal circuits and blood purifiers with dialysis fluid for the extracorporeal circulation of blood, cleaning them, and connecting them to the body.

The work is so specialized that clinical engineers and nurses learn basic the operations at universities and technical schools and then train for a certain period of time after entering the workforce. In order to reduce the hurdles to operating such dialysis machines, we have been working on the reduction of the burdens placed on operators by providing simplified tubing (blood tubing lines for dialysis), the installation of operation assistance functions, and so on.

The latest dialysis machines not only reduce the burden shouldered by medical personnel for preparing for treatment and undertaking operations for that treatment, but also reduce environmental impacts. They also come with functionality involving the linkage of devices located in the machine room with devices located in the dialysis room to make efficient use of disinfectant solutions, as well with mechanisms wherein the dialysate is manufactured and supplied in accordance with the number of people being treated that day.

—— I understand that you have recently enhanced the monitoring capabilities of your dialysis machines. What are the benefits yielded as a result of having done that?

Inoue: Our monitoring systems are designed to confirm the safety of treatment and to prevent problems before they occur.

For example, the effectiveness of dialysis treatment is evaluated by periodic blood tests, so you cannot immediately obtain information on the effectiveness of each individual instance of treatment. However, monitoring allows for real-time confirmation of indicators of treatment efficacy and for the rapid adjustment of treatment conditions to take place as needed.

With hemodialysis, it is also important to maintain stable extracorporeal circulation. During dialysis treatment, if the vascular condition of the puncture site deteriorates and extracorporeal circulation becomes unstable, treatment efficiency declines, which will often mean that stable treatment cannot be continued. Such changes can be detected at an early stage by utilizing monitoring functions, allowing for optimal treatment to take place that is tailored to the patient.

—— Next, I would like to ask you about blood purification devices. Can you first tell us how they work and the situations where they are used?

Ota: A blood purification device involves a mechanism by which blood is removed from the body, filtered to remove toxins and pathogenic substances, and is then returned back into the body. This device is not limited to specific patients, as is the case of hemodialysis for patients with chronic renal failure. It can be used for blood purification treatment involved in dealing with a wide range of diseases, including sepsis, acute renal failure, drug poisoning, and ulcerative colitis.

In some cases, it is used for acute care, particularly for patients brought into a facility by ambulance. For instance, blood purification devices are in situations such as when a patients that are brought into a facility by ambulance have experienced the crush syndrome* seen during earthquakes.

Mainly used for treatment in intensive care units, these devices require high levels of usability because they must be operated quickly and with precision.

*Crush syndrome involves muscle cell damage and necrosis that occurs when the body is released from pressure after being trapped for an extended period of time by a heavy object such as a house or car body.

——I have heard that compared to dialysis machines, blood purification devices are used less frequently and take more time to become proficient with. Is that true?

Inoue: That is exactly right. The hemodialysis treatment mentioned earlier takes time for setting everything up because many patients are treated simultaneously. Clinic staff, however, are familiar with the operations involved because they are frequently undertaken at a typical dialysis clinic.

Blood purification devices, on the other hand, are used infrequently since they are only used unexpectedly in cases where there are patients that require them. Although it depends on the application or medical institution involved, most of these devices are used at university hospitals and regional flagship hospitals for acute care, with limited numbers of staff being skilled in their operation.

In addition, blood purification devices, compared to dialysis machines used for hemodialysis treatment, have more complicated systems. Therefore, more time will be required for installing extracorporeal circuits, cleaning the blood purifiers, and learning how to do the preparatory tasks that are involved before treatment is to begin.

Efficiency improvements for the treatment preparations of blood purification devices to improve the quality of medical care: Nikkiso's inventions awarded regional invention commendations

—— Despite the fact that the devices are used in emergency situations, treatment preparation processes are complicated, aren't they? I understand that Nikkiso has invented technologies that solves such issues, with the invention of said technologies resulting in the receiving of the Kyushu Region Commendation for Invention and the Chubu Region Commendation for Invention.

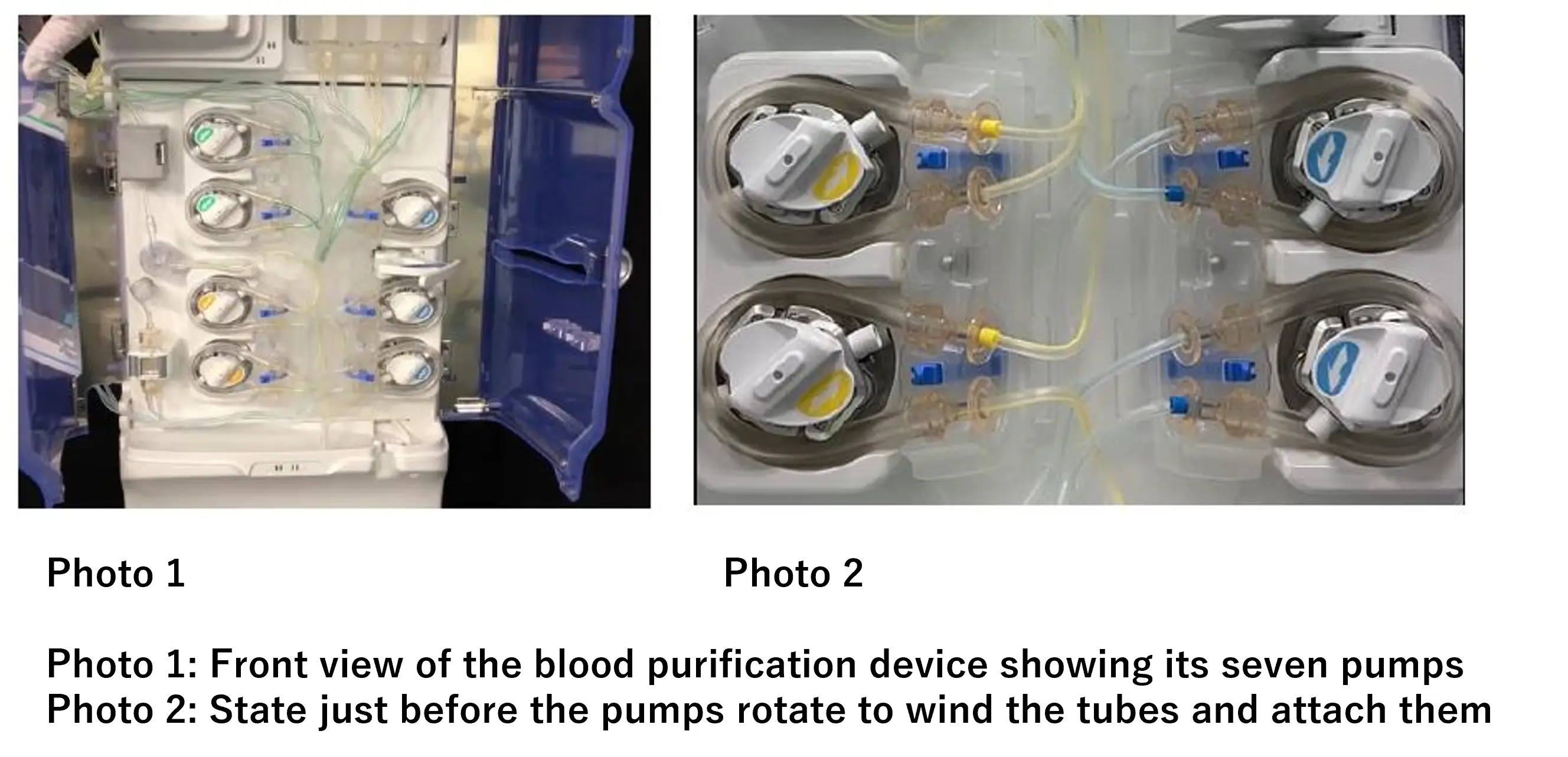

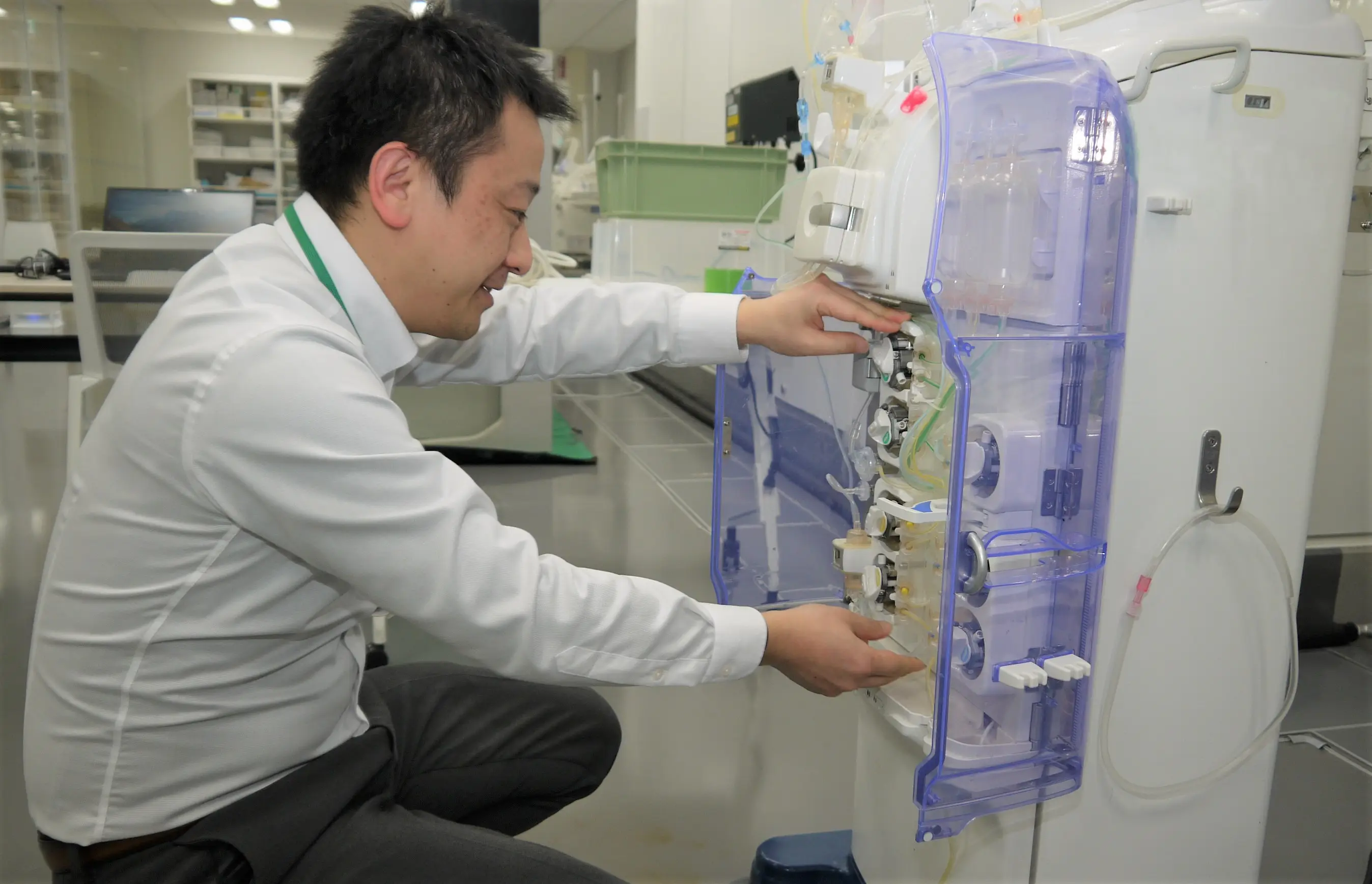

Morita: Yes. That's right. The Kyushu Region Commendation for Invention was awarded for the development of a mounting member serving to facilitate the automatic attaching and detaching of multiple extracorporeal circulatory circuit tubes to and from the pump's mounting area all at once. Sloped mounting members allow the tubes to be pressed neatly against the side of the device for easy installation. The cassette system, which holds seven tubes at the same time, allows for rapid treatment preparation to take place.

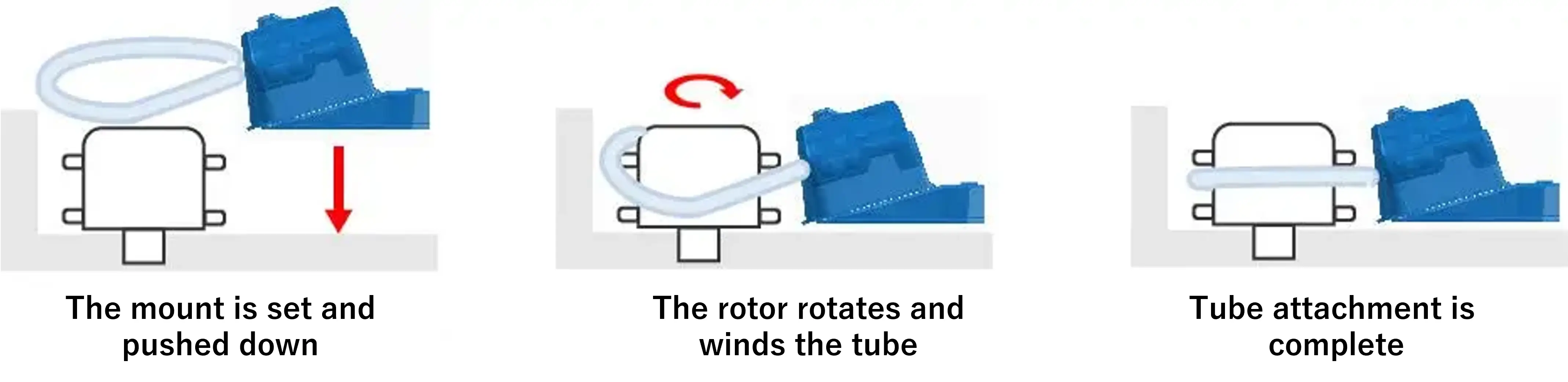

Ota: The Chubu Regional Commendation for Invention recognized the mechanism which enables automatic connection and disconnection of multiple extracorporeal circulatory circuit tubes all at once. The mechanism is such that after the tube is set in place, simply pushing the button makes the rotor of the pump automatically wind up and set the tubes in place.

—— How did you come to develop the mounting parts and the mechanism of the device?

Ota: One of the reasons we undertook development was the burdens on medical professionals for undertaking preparations for treatment. Blood purification devices are mainly used in emergency and intensive care units, where staff must be able to undertake treatment preparations as soon as possible. However, due to the infrequency of usage, many medical staff members are unfamiliar with how to operate these devices. Therefore, the medical community had required a design that would enable fast and accurate installation of complex extracorporeal circuits.

Therefore, we have been working on the development of a blood purification device that can be used to provide prompt and reliable treatment, taking advantage of our technological expertise in improving the efficiency and safety of hemodialysis treatment.

—— What specific needs have you seen arise in the medical community?

Morita: Seven types of pumps are installed within blood purification devices to pump blood, provide transfusions, and so on. Previously, tubes were installed manually one by one, which was time-consuming and resulted in mistakes being made, such as the installation of the wrong tube within the wrong pump.

That's why we have developed a technology on this occasion involving the attachment of tubing to multiple pumps at once, contributing to the saving of time and the reduction of errors.

—— What were some of the innovations made during development and what challenges were faced during the development process?

Ota: Our goal was to develop a device that would achieve high usability for medical professionals while keeping costs down. Tubes, in particular, are consumables and cannot cost much. Therefore, a major challenge that was faced was to ensure that the seven tubes could be installed reliably while at the same time placing an emphasis on cost-effectiveness.

Although we achieved relatively quickly the creation of technology wherein the attachment of each tube individually takes place, we did face difficulty to stably attach a 30 by 30-centimeter circuit to seven pumps at the same time.

Morita: The challenges I faced during development had to do with efficient winding and the removal of tubes with unstable shapes along with ensuring the strength of the mounting members, which are made from thin sheets. As for the tubes, we found the key point by analyzing the existing installation method and deducing the cause of the instability.

The breakthrough in improving operability was in folding and angling the components. This allows the tubes to be installed at an angle, ensuring stable winding and relieving any force placed on the tubes during removal. Another important point was the use of an integrated design involving the folding of the back of the seat. This meant that we achieved success in balancing operability and economic efficiency.

—— Can you tell us the honest impression you had after having received these awards and provide a few words about the thoughts you have now when you look back on the development processes?

Ota: When my receiving of the award had been decided, I was happy that my efforts to date had been recognized, and my family was extremely happy to hear the news as well.

I feel that this invention will help prevent operational errors in blood purification devices used in the acute phase and will lead to a dramatic improvement in terms of work efficiency. As for the next step, I would like to have us apply this technology to hemodialysis machines to achieve further progress.

Morita: I am very happy to have received this prestigious award. The development process was fraught with difficulties, and what particularly had us wracking our minds was the balance to be struck between high performance and low cost. I feel a great sense of accomplishment of having worked together with the members of my team to find a solution the challenges being faced and when it comes being finally able to bring this invention into reality despite the many failed attempts.

Aiming for efficient and innovative medical devices that support the continuance of medical care

—— What new development projects are you two currently working on and what are your plans for the future?

Ota: Our next goal is to improve the operability of dialysis machines and introduce more detailed monitoring functions.

Currently, medical professional manually adjust settings according to treatment conditions while monitoring the patient's condition. In the future, we hope to be able to automatically tailor treatment to each individual patient through system control.

Morita: I would like for us at the Manufacturing Engineering Department to support the development team. This development project constitutes a step toward the future. We are looking forward to further improving upon and advancing this technology.

—— What is your outlook on future product development in the Medical Business of Nikkiso?

Inoue: Japan is experiencing a declining birthrate and an aging population, and while burdens shouldered in terms of patient care are increasing, there is concern about a shortage of medical professional arising due to the declining population. Furthermore, the number of patients is expected to increase rapidly in overseas markets, where we are seeing economies are growing rapidly, since people who could not receive hemodialysis treatment in the past due to economic reasons will become able to receive that treatment.

Thus, as the global shortage of medical professional becomes more pronounced, there will be a need to streamline operations and support less experienced staff to ensure that treatment is provided which is safe and reliable.

The sustainability of medical care is also an important focus in the hemodialysis field. Hemodialysis is a treatment that must be performed over a long period of time unless a kidney transplant is performed, meaning that interruptions can be life-threatening for the patient. Health institutions have been preoccupied with the challenge of how to continue hemodialysis treatment with scarce manpower and supplies, especially during times of disaster and infectious disease outbreaks.

Against this backdrop, the provision of safe, efficient, and simplified medical services is something that is extremely important. Our primary goal as a company is to contribute to the continuity and development of medical care.

Pickup

-

MEDICAL FIELD

MEDICAL FIELD

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

MANUFACTURING

MANUFACTURING

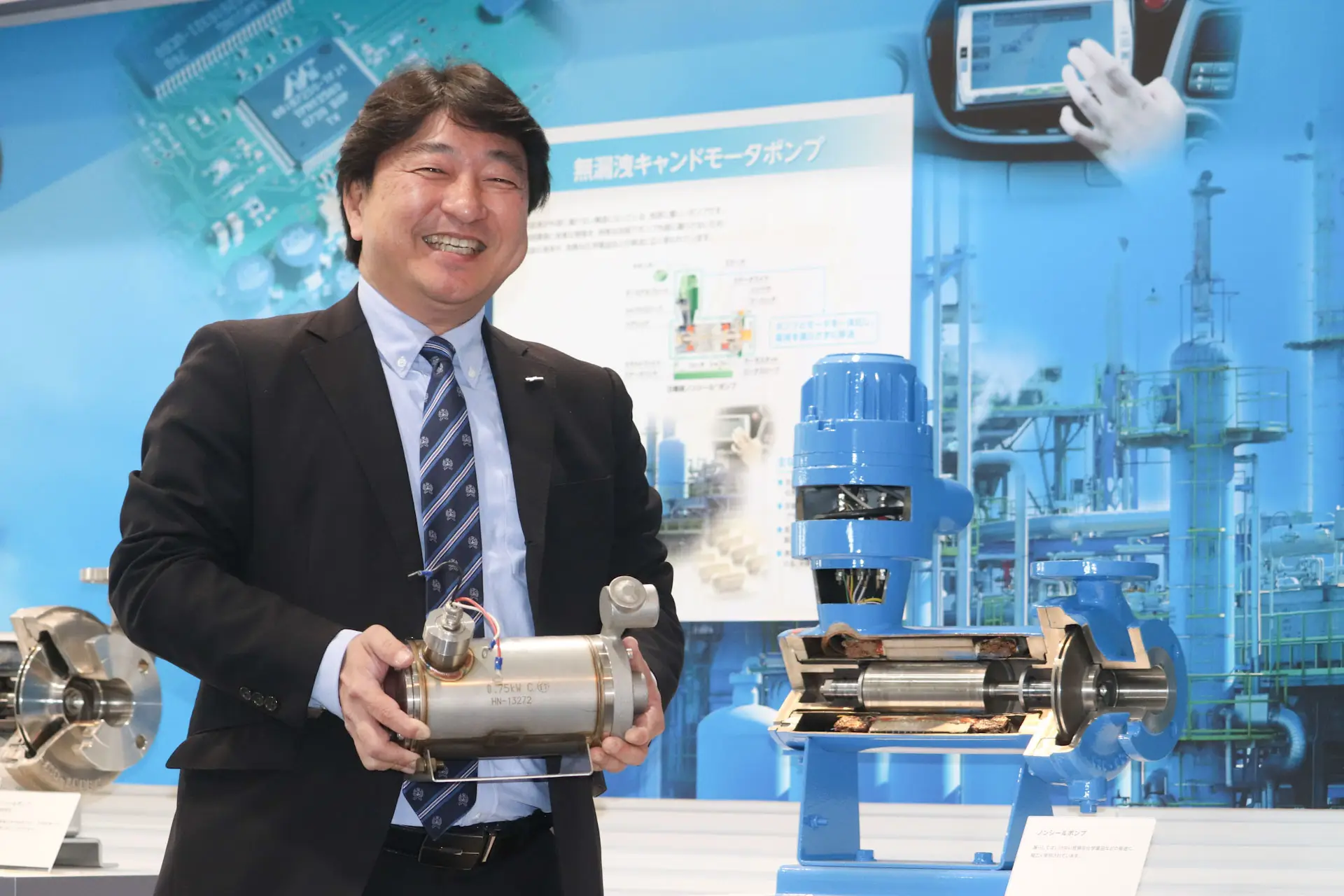

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

MANUFACTURING

MANUFACTURING

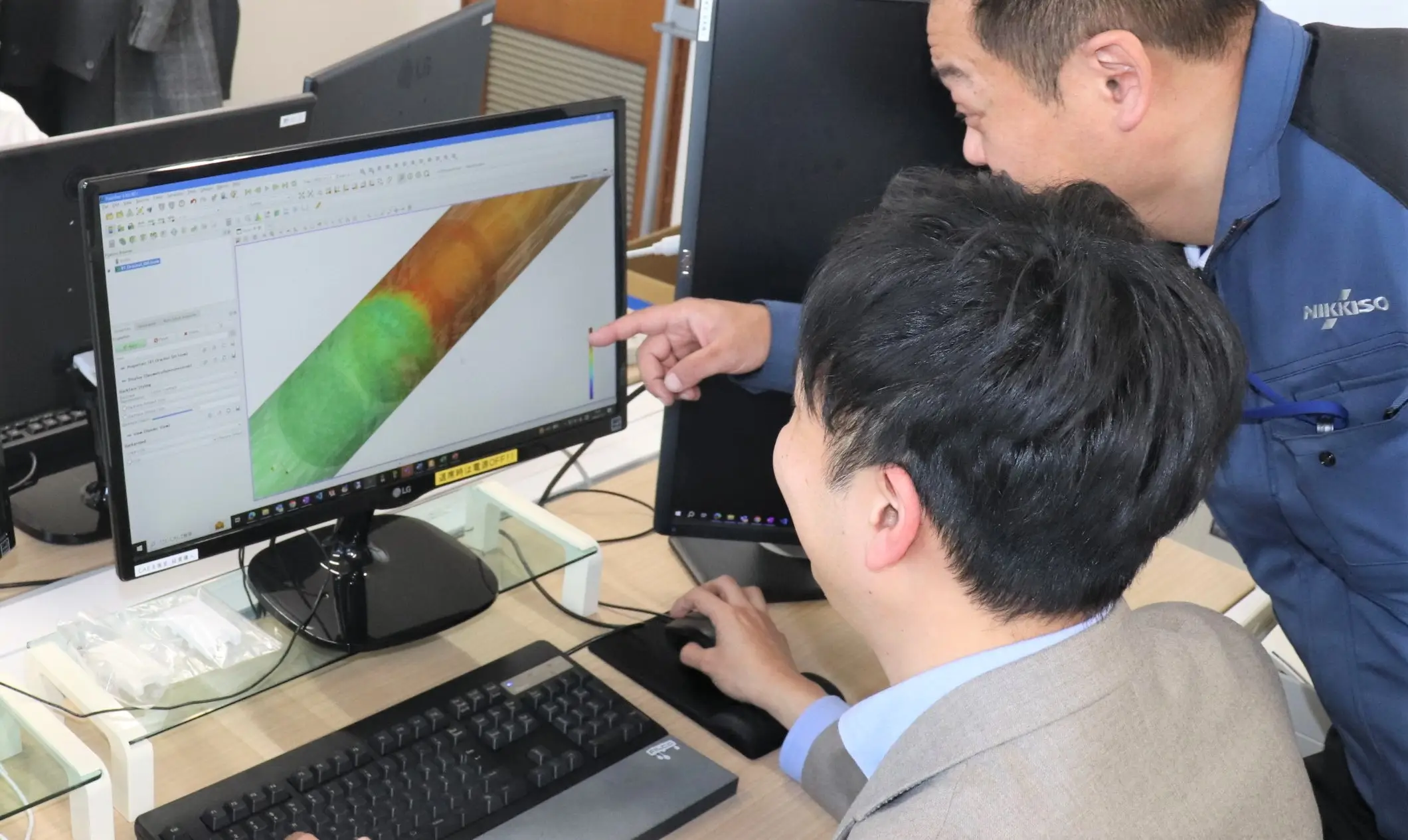

Nikkiso's DX initiatives: CAE Support Department continues to evolve, aiming to eliminate dependence on the skills and expertise of specific people

- Technology

- Interview

2025/04/09

関連記事

-

MEDICAL FIELD

MEDICAL FIELD

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

MEDICAL FIELD

MEDICAL FIELD

A region on the forefront of dialysis treatment: Nikkiso automation gathering attention in Europe

- Medicalbusiness

- Hemodialysis

- Interview

2025/03/13

-

![[Dialysis Medical Care and SDGs #2] Treatment Options: What is Sustainable Dialysis Medical Care in the Future?](/media/kMxvJwAdHOfgot6LqeZcH0WkXH45Q5buehtbuYnK.jpg) MEDICAL FIELD

MEDICAL FIELD

[Dialysis Medical Care and SDGs #2] Treatment Options: What is Sustainable Dialysis Medical Care in the Future?

- Hemodialysis

- Interview

- Medicalbusiness

2024/06/21

-

![[Dialysis Medical Care and the SDGs #1] Issues Surrounding Dialysis Medical Care: Thinking about Environmental Issues and Workstyles](/media/7yoD8Mt0CeKw1lmWAfmKhOeq6M4fDhEkiknclkG8.jpg) MEDICAL FIELD

MEDICAL FIELD

[Dialysis Medical Care and the SDGs #1] Issues Surrounding Dialysis Medical Care: Thinking about Environmental Issues and Workstyles

- Interview

- Hemodialysis

- Medicalbusiness

2024/06/14