ENRICH OUR LIVES

2024/05/08

Secret to the Odor of Gas

- Pump

- LNG

- Industrial

Index

That peculiar odor you notice when you fail to turn on a gas stove...

Actually, it is not a natural gas odor, but an artificial odor added to the gas so that people can notice a gas leak.

This story explains the secret of this gas odor in detail.

Gas is naturally colorless and odorless

City gas is made from liquefied natural gas (LNG) mainly composed of methane, and propane gas is made from liquefied petroleum gas (LPG) mainly composed of propane and butane. Both LNG and LPG are odorless.

Therefore, for security reasons such as preventing incidents by enabling the detection of even minor gas leaks as quickly as possible, the Gas Business Act stipulates that an odor must be added to gas using an odorant (odorization).

Odorants with odors that are unpleasant to humans are intentionally selected so that any danger can be detected easily, and

tertiary butyl mercaptan, which is said to smell like rotten onions,

dimethyl sulfide, which is said to smell like garlic, and

cyclohexene, which is said to smell like petroleum

are used as their components.

Gas odorization methods

So, how is an odor added to gas?

There are three major methods for odorizing gas as listed below, from which the most suitable method is selected according to the size of the facility, the type of odorant used, and other conditions.

Pump injection method

With this method, a liquid odorant is injected directly into a gas pipe using a pump, and the odorant vaporizes to diffuse the odorizing component. The amount of injected odorant can be changed with the pump according to the gas flow rate.

Evaporation method

With this method, evaporated odorant is mixed with the gas. Since evaporated odorant is mixed into the gas, a pump is not required. However, when an odorant contains a mixture of several components, it is difficult to odorize the gas evenly because the different components evaporate at different times. As such, it is said that single-component odorants are more suitable.

Liquid odorization method

With this method, an odorant is injected directly into liquefied propane gas (LPG), which is the raw material. It is a simple odorization method in which adjustments to the liquid volume are not required.

The pump injection method can handle various amounts

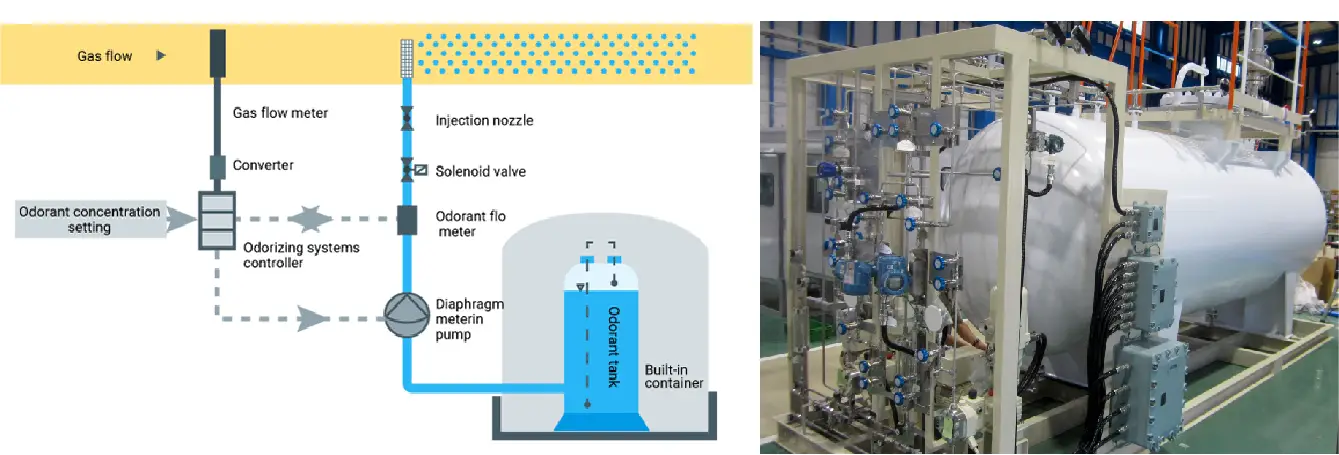

Of these three odorization methods, the adoption of the pump injection method is increasing. This method can be used for a wide variety of environments from small to large facilities, because the amount of an odorant injected can be changed according to the gas flow rate. Even LNG terminals use odorizing systems based on the pump injection method.

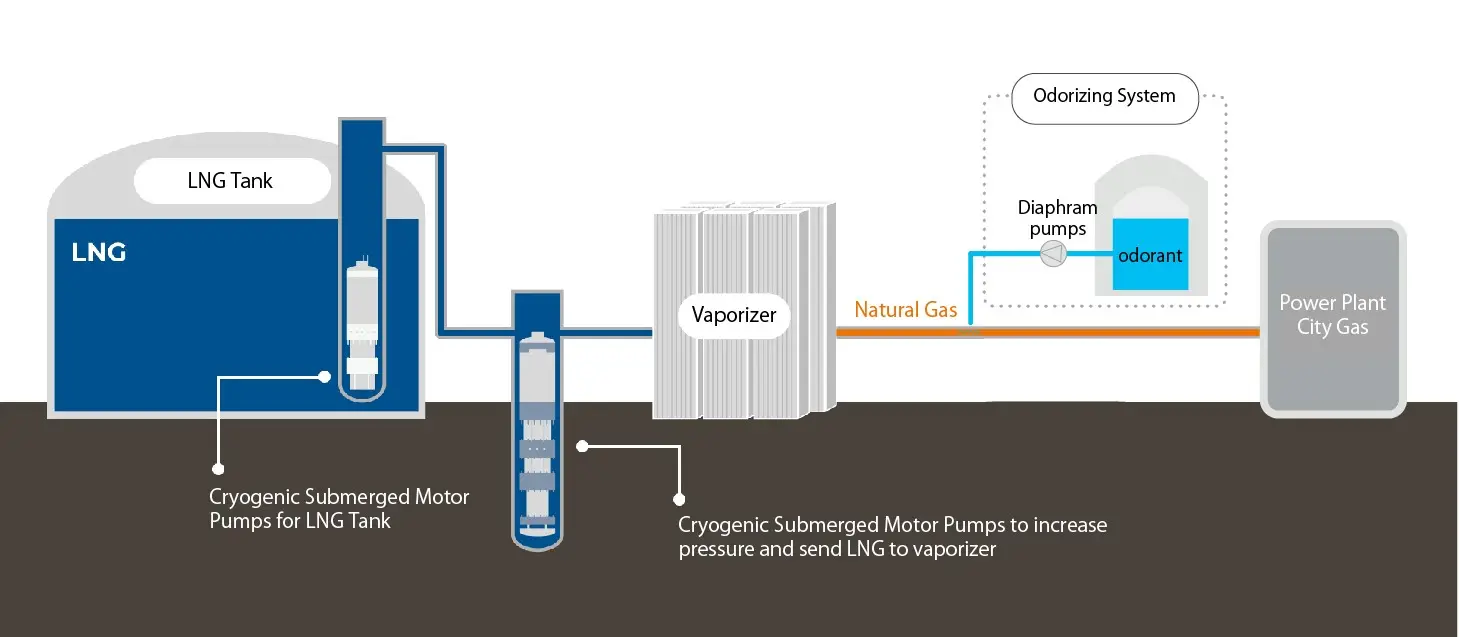

LNG is transported by ship from overseas, stored in LNG tanks at a terminal, and then returned to gas by a vaporizer. During this process, the gas is odorized by an odorizing system at the same time.

Pump technology without leakage required for odorizing systems

Since odorizing systems handle undiluted solution of gas odors, they are specifically required to prevent odors from leaking. Because undiluted odorant solution has a smell tens of times stronger than gas used at home, even a slight leak can be easily detected as an odor that is unpleasant to humans, and people may mistakenly think that gas is leaking even when there is no gas leak. To prevent such mistakes, it is very important to prevent odor leakage.

With the pump injection method, it is also necessary to inject odorants accurately at a fixed concentration according to the gas flow rate.

For this reason, reciprocating pumps that can accurately inject a fixed amount of an odorant are used for odorizing systems based on the pump injection system. Since reciprocating pumps are sealed with a diaphragm, they can inject liquids with a high degree of discharge accuracy even under high pressure without any leakage.

In addition, reciprocating pumps can change the injected amount in response to changes in the gas volume by controlling the motor speed of the pump and the stroke length of the reciprocating motion, thereby keeping the concentration of the gas odor constant.

Reciprocating pumps (diaphragm pumps)

Reciprocating pumps (diaphragm pumps)

Nikkiso's specialized pumps and odorizing systems

Nikkiso also produces odorizing systems based on the pump injection method with a high degree of discharge accuracy and safety, and has delivered more than 200 odorizing pumps in Japan.

Nikkiso combines pipes to connect pumps, valves to open and close liquid flows, tanks to store odorants and other chemical solutions, pressure gauges to check pressure in pipes, flow meters to measure the flow rate of liquids, and other devices, in addition to pumps, as a single system.

Odorizing system diagram (example)

Odorizing system diagram (example)

Summary

For security reasons, an odor that is unpleasant to humans is intentionally added to otherwise colorless and odorless gas. Specialized pumps that can inject a fixed amount of an odor without leakage are used for odorizing gas. The machines used to odorize gas are called odorizing systems.

In addition to pumps, Nikkiso has an extensive track record of delivering package systems that include pumps. Nikkiso also produces odorizing systems by taking advantage of its fundamental knowledge of packaging and accumulated know-how on odorant pumps.

Please contact Nikkiso for inquiries about pumps and odorizing systems for gas odorization, and package systems.

Pickup

-

MEDICAL FIELD

MEDICAL FIELD

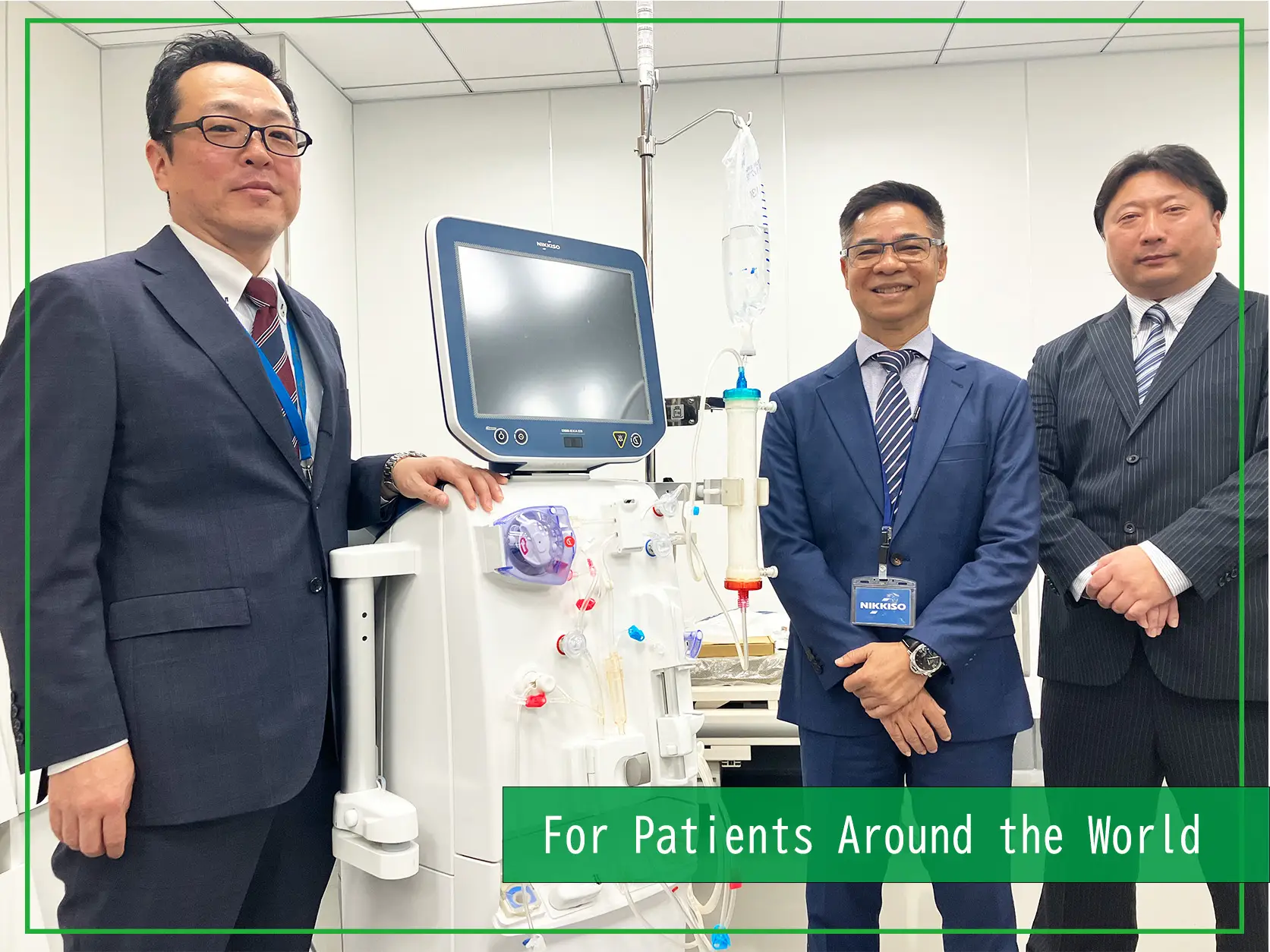

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

MANUFACTURING

MANUFACTURING

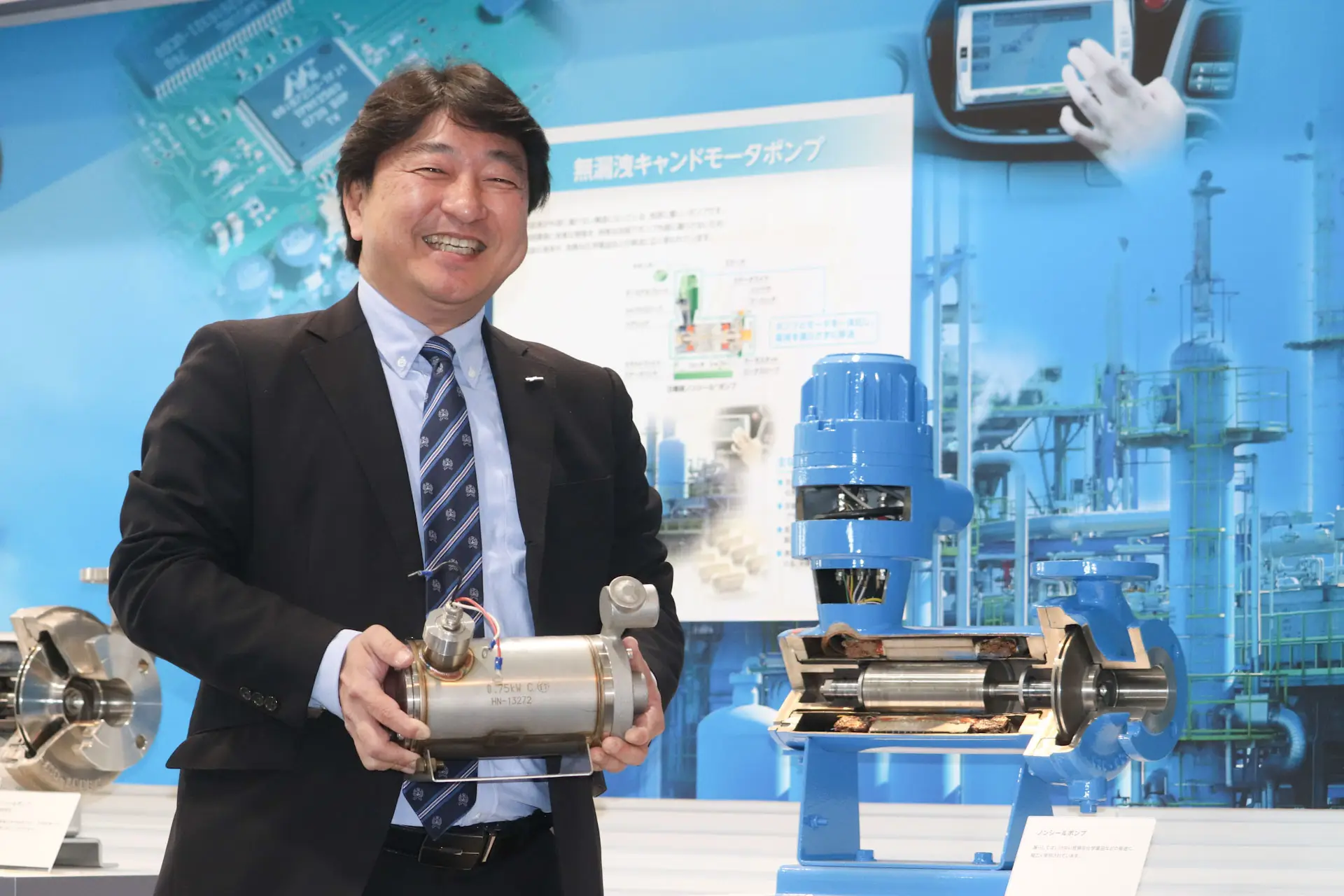

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

MANUFACTURING

MANUFACTURING

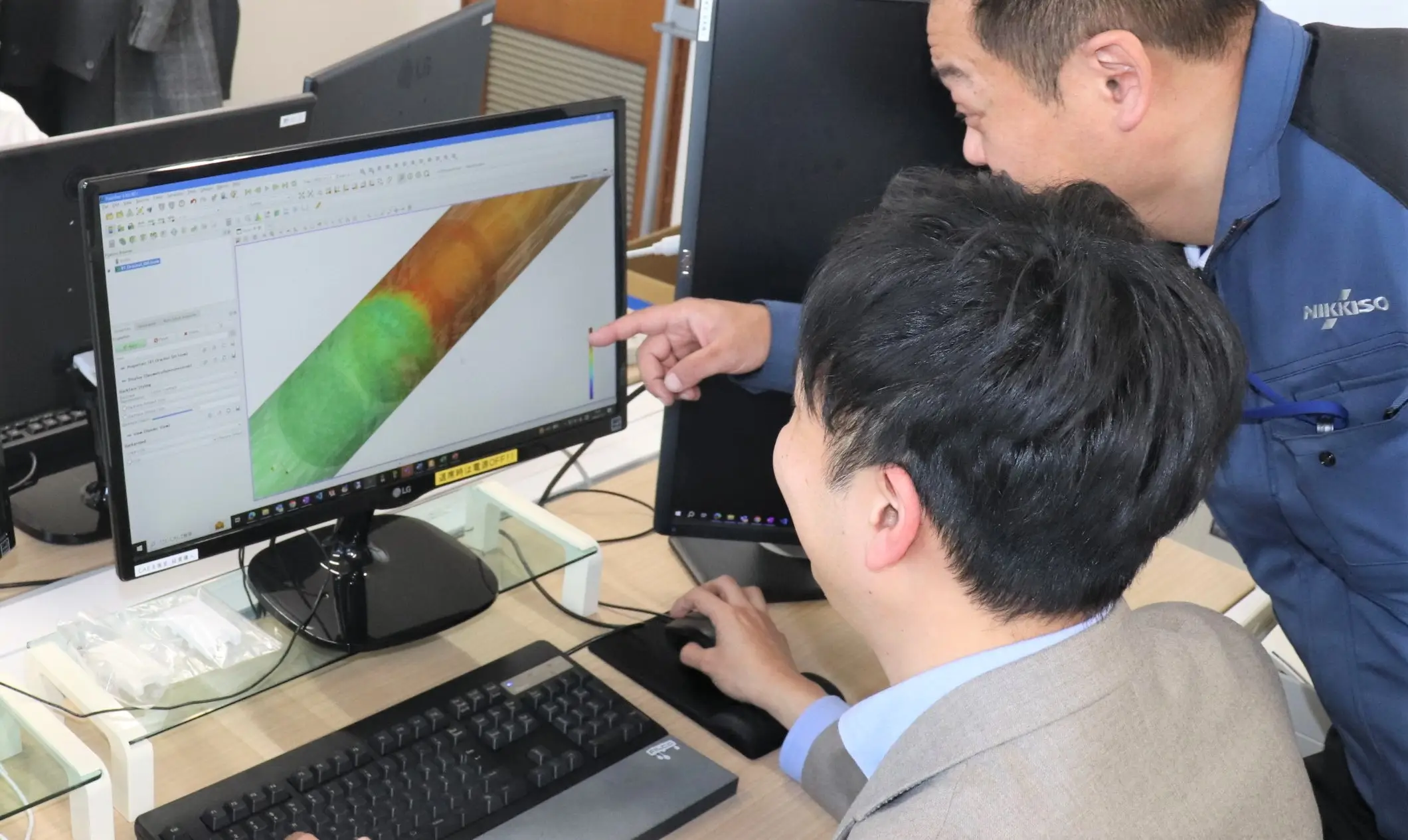

Nikkiso's DX initiatives: CAE Support Department continues to evolve, aiming to eliminate dependence on the skills and expertise of specific people

- Technology

- Interview

2025/04/09

関連記事

-

ENRICH OUR LIVES

ENRICH OUR LIVES

How does an airplane stop? Secrets of the cascade, an essential component for deceleration

- CFRP

- Aircraft

- Aerospace

2024/09/12

-

ENRICH OUR LIVES

ENRICH OUR LIVES

What exactly is the SiC power semiconductor that is essential for decarbonization and the popularization of EVs? Here is some basic knowledge and information on future prospects

- Decarbonation

- Technology

- Industrial

- Semiconductor

2023/11/20

-

ENRICH OUR LIVES

ENRICH OUR LIVES

Decarbonizing the skies with hydrogen aircraft? Useful basic knowledge, the state of development, and everything in between

- Hydrogen

- Decarbonation

- Aircraft

- Pump

- CFRP

- Industrial

2023/10/17

-

ENRICH OUR LIVES

ENRICH OUR LIVES

When will eVTOLs become practical? A thorough explanation of everything from the basics

- CFRP

- eVTOL

- Aircraft

2023/09/06