ENRICH OUR LIVES

2023/11/20

What exactly is the SiC power semiconductor that is essential for decarbonization and the popularization of EVs? Here is some basic knowledge and information on future prospects

- Decarbonation

- Technology

- Industrial

- Semiconductor

Index

Now is a time when solving the problem of climate change is a common issue to everyone around the globe and when movement toward decarbonization is accelerating.

According to the IEA’s publication “Net Zero by 2050,” about 20% of the world’s carbon dioxide is emitted from the transportation sector. The automobile industry accounts for about three fourths of that.

In order to achieve decarbonization, it is said that decarbonization is essential in the automotive industry. Thus, efforts are currently underway to develop and promote electric vehicles (EVs).

[Reference: IEA; “Net Zero by 2050”; https://www.iea.org/reports/transport]

Against this backdrop, SiC (silicon carbide) power semiconductors are seeing increased demand and are attracting attention. In this article, we will explain in detail the roles played by and the characteristics of SiC power semiconductors, market trends, the state of development, and prospects for the future.

Growing demand for EVs when it comes to achieving decarbonization

In response to the intensification of climate change, efforts have been made around the world to achieve “decarbonization,” which means reducing greenhouse gas emissions (which constitute one of the major contributing factors to climate change) to zero as a whole.

Decarbonization requires that efforts be undertaken in various sectors, which includes at households, local governments, and within the various industries. One of the most important elements involved is the collection of efforts being undertaken in the transportation sector, particularly when it comes to automobiles.

As countries around the world work on the electrification of their power sources, expectations when it comes to the development and spread of electric vehicles (EVs) are growing.

According to “Net Zero by 2050” published by the International Energy Agency (IEA), it is being said that more than 60% of global car sales need to be for EVs by 2030 in order to achieve net zero worldwide by 2050 when it comes to cars. The European Union has accelerated its moved toward the transition to EVs as evidenced by occurrences such as its announcement of a policy to ban the sale of internal combustion engine vehicles (such as gasoline and diesel vehicles) by 2035.

(Reference: Nihon Keizai Shimbun; “EU to ban the sale of ICE cars by 2035”)

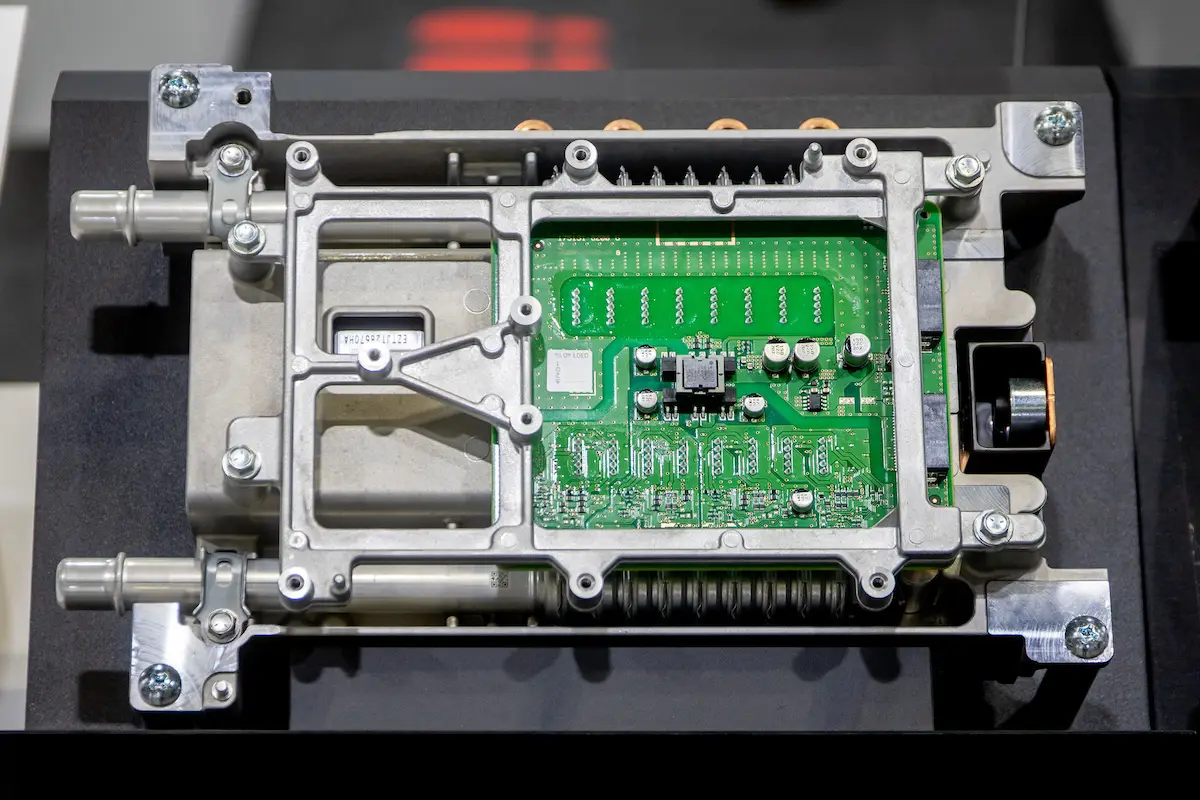

Power Semiconductors Required for the Popularization of EVs

Automobiles use semiconductors which serve to control all kinds of movements (including engine braking) and serve to control power.

There are several types of semiconductors used in vehicles, but EVs require higher voltages and higher capacities than ordinary vehicles do. This means that semiconductors that are able to handle such large voltages and currents, are required. This is where “power semiconductors” come into play.

Because of their high resistance levels when it comes to voltage and power, power semiconductors are used for the control of not only automobiles, but also for the control of industrial equipment, electric power, railways, and home appliances.

The performance of power semiconductors, which can be used in such a wide range of situations, has been improved through continuous development. Physical limitations, however, have been pointed out. Such limitations include the probable difficulty involved in improving the performance of current silicon (Si) materials.

Therefore, SiC (silicon carbide) power semiconductors are receiving increasing amounts of attention as an avenue through which to achieve improved efficiency and the miniaturization of Si power semiconductors, which currently constitute challenges that are being faced when it comes to Si power semiconductors.

SiC power semiconductors to accelerate the popularization of EVs

This section provides an overview and introduction to the features of SiC power semiconductors, whose demand is expected to increase rapidly in the future.

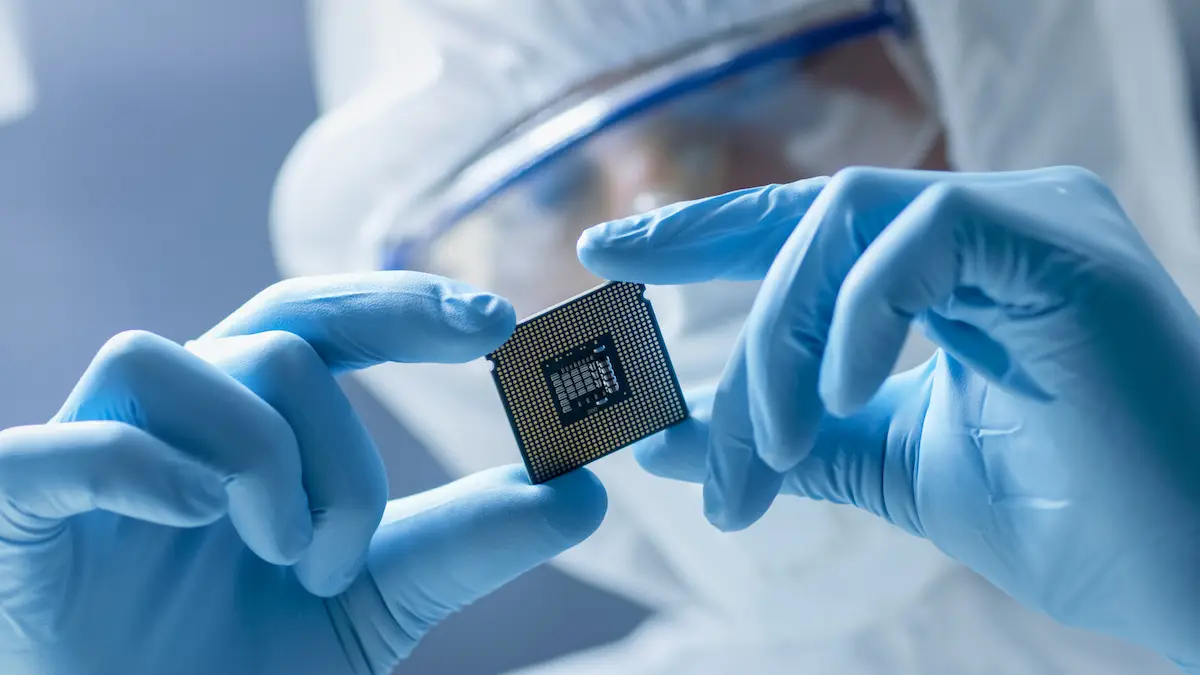

What is a SiC power semiconductor?

SiC power semiconductors are semiconductors whose main material is silicon carbide (SiC), a compound consisting of silicon (Si) and carbon (C).

Research and development have been underway in Japan and around the rest of the world since the 1990s. In 1998, the New Energy and Industrial Technology Development Organization (NEDO) launched a project to commercialize the technology. Through these efforts, mass production was achieved. In 2014, practical realization was achieved with railroad cars.

Features of SiC power semiconductors

SiC power semiconductors have the following characteristics when compared with Si power semiconductors.

- Ability to withstand higher voltages, currents, and operating temperatures

- There is little loss of energy when controlling the electric power since the thickness of places where the electrical resistance occurs can be reduced to about 1/10

- The heat dissipation mechanism purposed with reducing heat generation arising due to the loss of energy (usually all heat is released) can be miniaturized and simplified, thereby achieving the miniaturization of equipment

- The lower the energy loss, the more efficient the device that controls the power, which means the greater the distance that can be covered on a single charge, and so on

It is expected that as a result of the leveraging of these characteristics, SiC power semiconductors will serve as a replacement for Si power semiconductors and play the role of supporting the popularization of EVs as a “next-generation power semiconductor” with the ability to make higher performance and energy saving a reality.

Future prospects of SiC power semiconductors

Next, let’s take a look at the market and the moves being made by each company related to SiC power semiconductors. Then, let’s look at the prospects for the future when it comes to development.

Industry trends when it comes to SiC power semiconductors

In May 2022, Fuji Keizai announced that the global market for SiC power semiconductors is expected to reach 120.6 billion yen in 2022 and 969.4 billion yen by 2030, based on a global market survey concerning power semiconductors.

【Global market for power semiconductors】

| Forecast for 2022 | Compared to 2021 | Prediction for 2030 | Compared to 2021 |

Si power semiconductors | 2,213.7 billion yen | 110.0% | 4,311.8 billion yen | 2.1times |

SiC power semiconductors | 120.6 billion yen | 159.5% | 969.4 billion yen | 12.8times |

Against the background of progress seen in terms of the electrification of automobiles being undertaken in the move toward decarbonization, demand for SiC power semiconductors is expected to expand significantly as electric cars (EVs, etc.), and charging infrastructure, become more widespread. Further replacement of Si power semiconductors is also expected to increase as prices fall.

[Reference: Fuji Keizai Press Release “Research on the Global Market for Power Semiconductors”; 2022.05)]

Amid expectations of growth in terms of demand and the global market, various domestic moves have been made in relation to the process spanning from the production and implementation of SiC power semiconductors within society at large.

Until now, there have been few vehicles made by Japanese manufacturers that have been equipped with SiC power semiconductors. This situation, however, has changed significantly. EVs produced by non-Japanese manufacturers, which are equipped with SiC power semiconductors, have seen increased sales and are expected to see further market growth. In October 2022, Toyota Motor Corporation and Honda announced the adoption of SiC power semiconductors for their EVs, which constitutes a piece of evidence that we are seeing evidence of progression when it comes to the entry of Japanese manufacturers into the market.

In cooperation with the automobile industry, the government and research institutions, efforts are currently underway to establish technologies for mass production and to revive the Japanese semiconductor industry.

Development of SiC power semiconductors and the future

The Ministry of Economy, Trade and Industry has set the following two R&D targets based on market forecasts and technological challenges for next-generation power semiconductors, including SiC power semiconductors.

- Reducing energy loss of equipment using next-generation power semiconductors by 50% by the year 2030, and achieving the same cost as Si power semiconductors at the same time

- Reduce defect density (defects per unit area = number of issues in terms of materials) by at least one order of magnitude in 8-inch (200-mm) SiC wafers (boards used as materials for semiconductor components) by 2030

[Reference: The Ministry of Economy, Trade and Industry; “Overview of the R&D and Societal Implementation Plan (Draft) for the ‘Building Next Generation Digital Infrastructure’ Project” (2021.07)]

To achieve these goals and have that lead to the acquisition of market share and to societal implementation...

- Developing new digital control technologies suitable for next-generation power semiconductors that operate at higher speeds than Si power semiconductors in order to reduce energy loss

- Finding an optimal manufacturing method which allows for both an increase in the diameter of the wafer to reduce costs and the improvement of the quality of the materials used for the wafer

- Improving both wafer fabrication techniques and fabrication techniques for devices using power semiconductors in order to reduce wafer defects

...along with other technical challenges, still remain. Progress is being awaited when it comes to joint efforts by industry, government and academia.

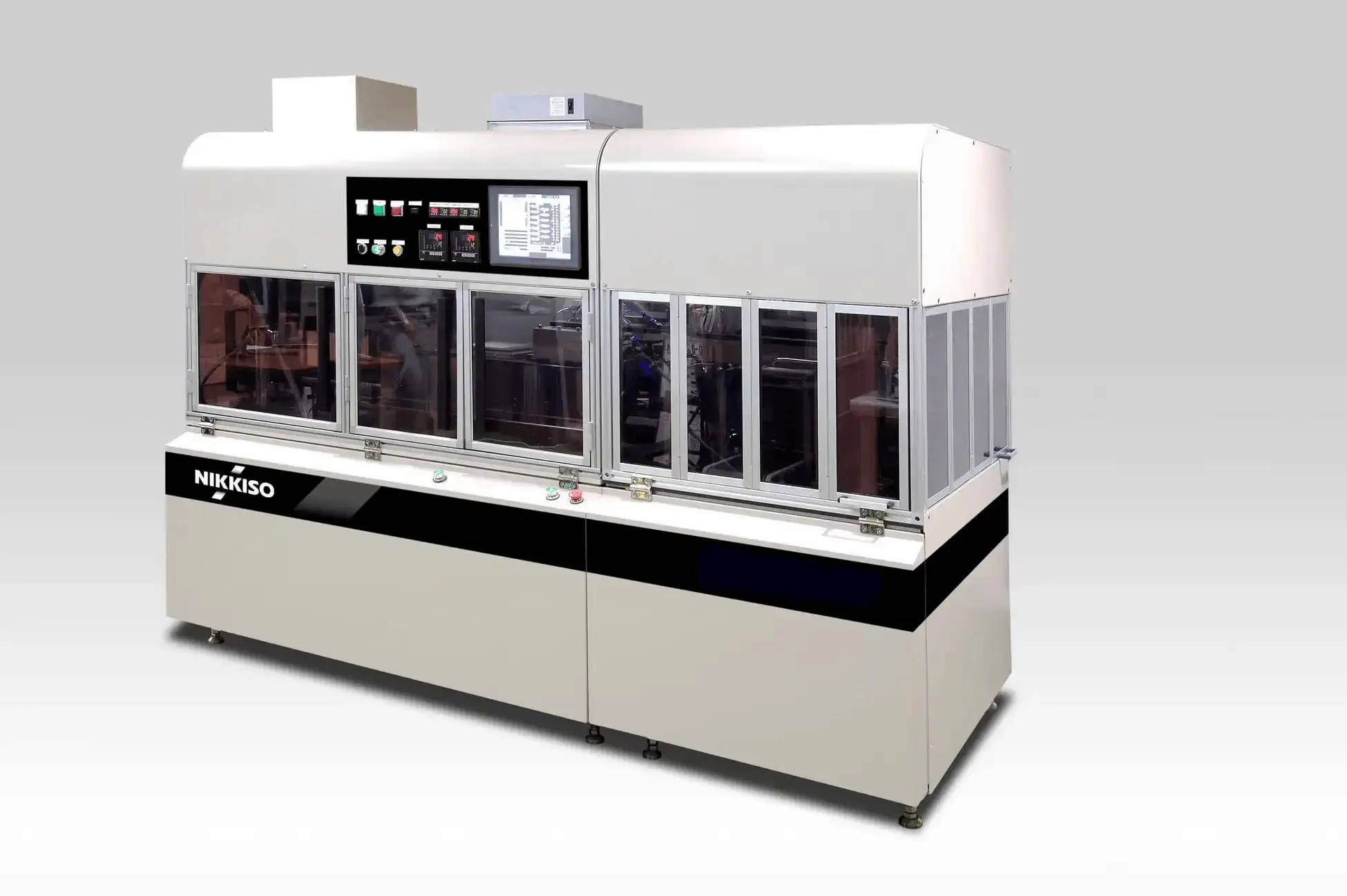

Nikkiso’s sintering equipment

When it comes to making electronic circuits by bonding SiC power semiconductors to substrates, conventional solder-based bonding does not allow for the sufficient exertion of performance of SiC power semiconductors (which can be used at high temperatures due to the low melting point of the solder). As such, we are seeing more manufacturers move to the deployment of methods of sintering involving the usage of bonding agents made of silver or copper (sintering meaning hardening a temperature lower than the melting point).

Nikkiso has developed a product it calls the 3D Sinter, which is equipment used in the process of sintering and bonding SiC power semiconductors and substrates.

With the conventional “metal press method,” the planar application of pressure meant that the part where the bonding agent is extruded (the fillet part) was not subject to the application of force, which made the part brittle. What’s more, it was necessary to replace the mold according to the height and wiring pattern of the chip and substrate involved, and much time was required when it came to changing arrangements around. There were also other problems involved such as the cost of the mold.

On the other hand, the “3D press method” used with the 3D Sinter, uses a special gel-like pressurizing medium for three-dimensional pressurization.

This makes it possible to apply solid, uniform pressure to the fillet parts to prevent chipping and improve their quality. It also makes it possible to join even substrates characterized by unevenness in terms of the height of the surfaces upon which chips are mounted all at once, thereby increasing productivity when it comes to equipment manufacturing and reducing running costs.

This 3D press system is based on technologies involving “uniform pressure and uniform heating” which Nikkiso has cultivated throughout its journey providing the Warm Isostatic Laminator, which is widely used as an industry standard machine for crimping MLCCs.

Leveraging 3D sintering technology, Nikkiso is also developing a 3D press for the manufacture of metal substrates, which are seeing growth in terms of demand for usage in EVs.

Nikkiso will continue to develop equipment which leverages our unique technological capabilities and experience. The company committed to contributing to the spread of next-generation power semiconductors and EVs and to contributing to the future achievement of a decarbonized society.

Summary

Demand for power semiconductors is growing. They play an important role in the electrification of everything (including automobiles) as we move to bring to fruition a decarbonized society. There are particularly heightened expectations when it comes to SiC power semiconductors, which are characterized by high performance and allow for energy conservation. Efforts are also being made in terms of development and their implementation throughout society.

During the manufacturing process of equipment using SiC power semiconductors, Nikkiso has developed a product called “3D Sinter,” which enables high-quality, high-efficiency, and low-cost bonding of SiC and substrates. The company is committed to responding to the increasing demand for SiC power semiconductors by developing this equipment and contributing to decarbonization.

Pickup

-

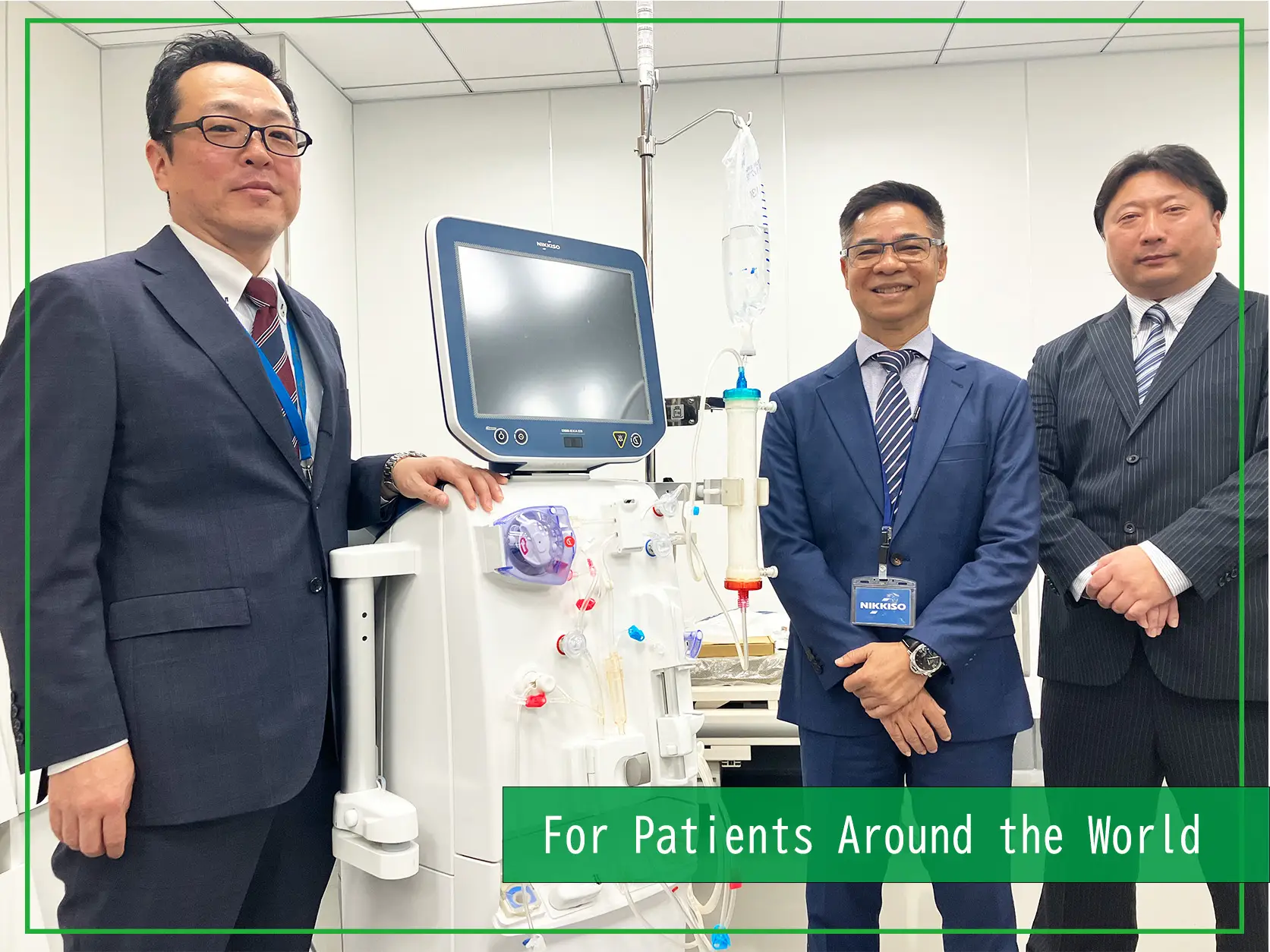

MEDICAL FIELD

MEDICAL FIELD

Empowering Asia’s Expanding Dialysis Treatment with Nikkiso’s Advanced Technology and Comprehensive Support

- Hemodialysis

- Interview

- Medicalbusiness

2025/10/30

-

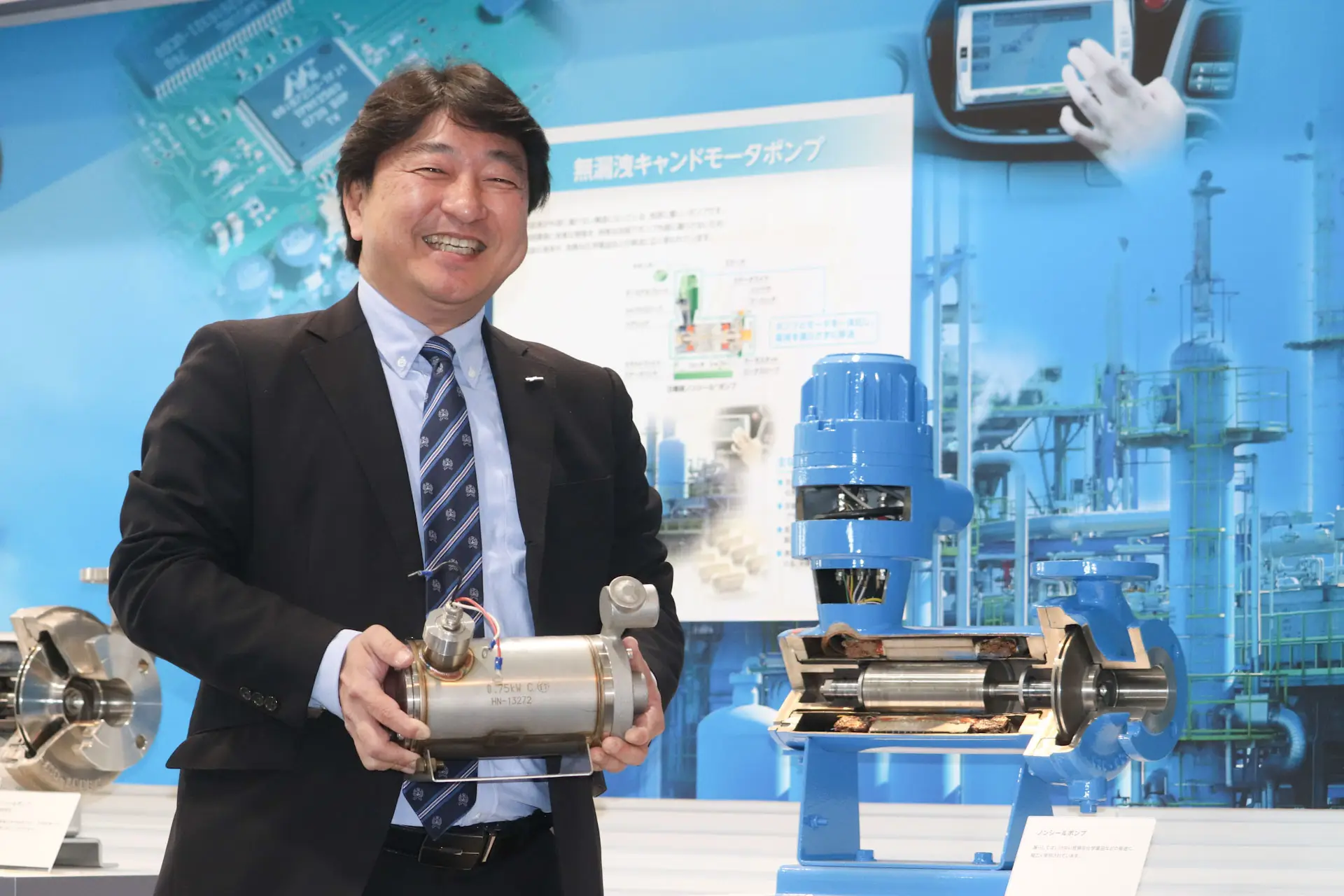

MANUFACTURING

MANUFACTURING

Pumps also actively used in semiconductor manufacturing: 20 years of history of compact, high-speed canned motor pumps

- Technology

- Interview

- Pump

- Semiconductor

2025/05/21

-

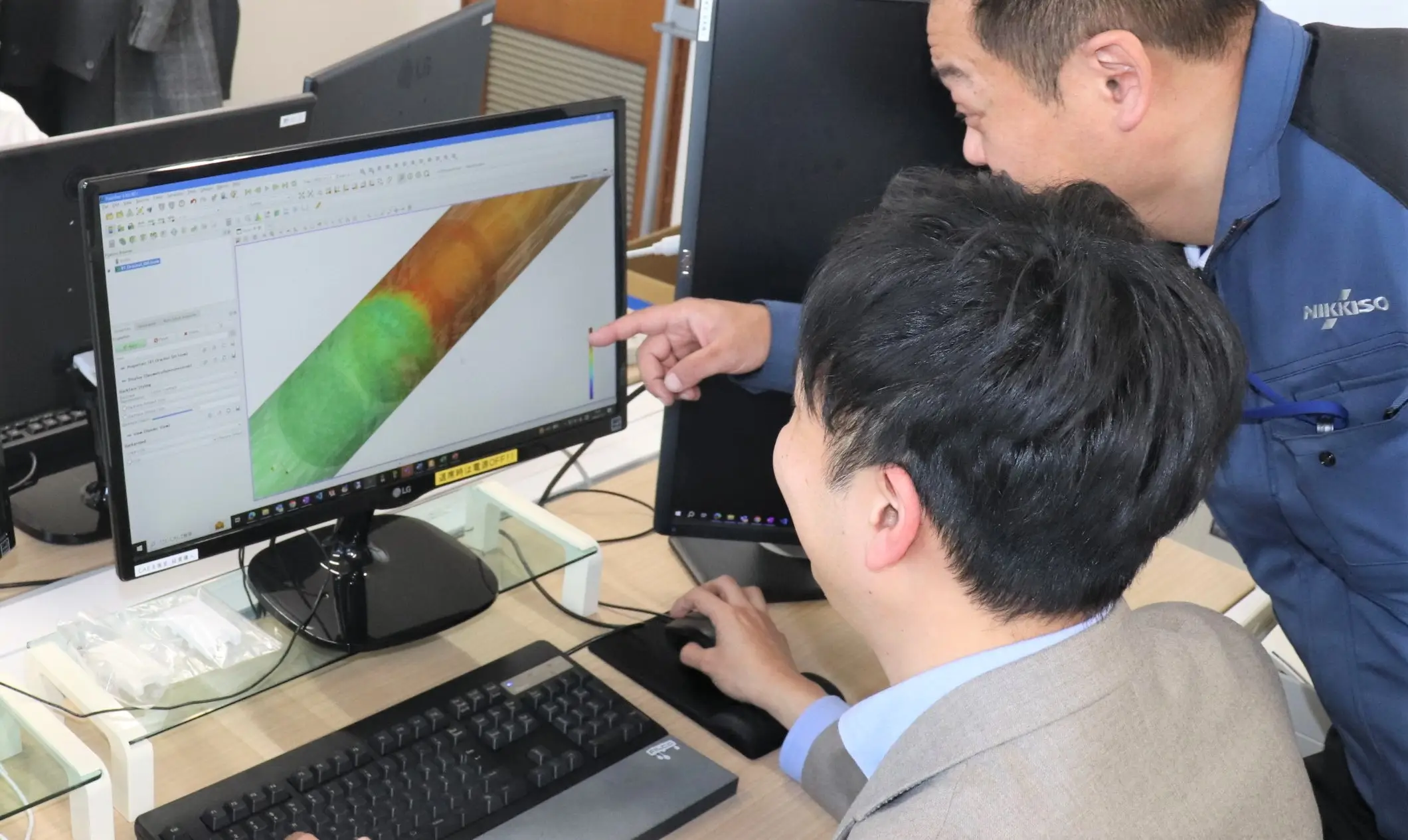

MANUFACTURING

MANUFACTURING

Nikkiso's DX initiatives: CAE Support Department continues to evolve, aiming to eliminate dependence on the skills and expertise of specific people

- Technology

- Interview

2025/04/09

関連記事

-

ENRICH OUR LIVES

ENRICH OUR LIVES

How does an airplane stop? Secrets of the cascade, an essential component for deceleration

- CFRP

- Aircraft

- Aerospace

2024/09/12

-

ENRICH OUR LIVES

ENRICH OUR LIVES

Secret to the Odor of Gas

- Pump

- LNG

- Industrial

2024/05/08

-

ENRICH OUR LIVES

ENRICH OUR LIVES

Decarbonizing the skies with hydrogen aircraft? Useful basic knowledge, the state of development, and everything in between

- Hydrogen

- Decarbonation

- Aircraft

- Pump

- CFRP

- Industrial

2023/10/17

-

ENRICH OUR LIVES

ENRICH OUR LIVES

When will eVTOLs become practical? A thorough explanation of everything from the basics

- CFRP

- eVTOL

- Aircraft

2023/09/06